Inks for every substrate

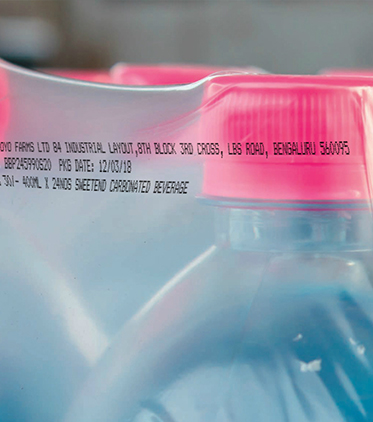

Range of inks for multiple substrates

Extensive range of Dye & Pigment based inks for Dairy Industry

Quick Line Changover

The KGK Jet Versatile coding machine applies codes to bottle caps, the base, on labels, or directly onto packaging.

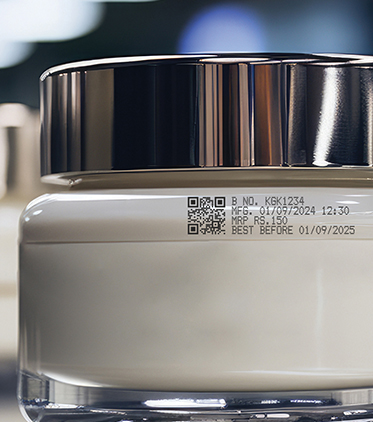

Fighting the Duplicate/Fake products

Specialised invisible Fluorescent ink which will be

visible in UV light only

High Quality Permanent Marking

KGK UV, CO2 & Fiber laser code up to speed, 700 Products per minute

Fastest Printing can start in just 24 seconds

Nozzle capping Technology, eliminates the need to replace the ink in the head with a solvent, reducing solvent consumption and eliminating the need to worry about the ink becoming diluted when restarting operation.

- The world's fastest printing machine can be started in just 24 seconds from a stopped state.

- Printing can be started in approximately 16 seconds from the printable state to the stopped state.