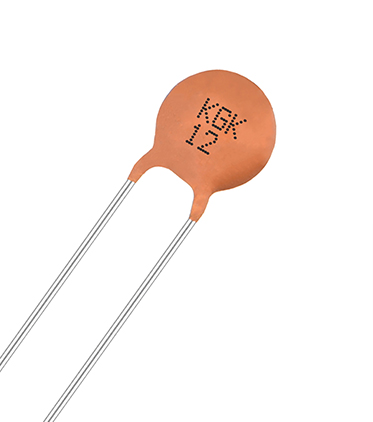

Coding on Ceramic

Marking on ceramic surfaces can be challenging due to their hardness, smoothness, and sometimes porous nature. However, KGK Jet CIJ machines are designed to handle such tasks efficiently.

Ink Selection: Special inks are used for ceramic substrates, including MEK-based, UV-curable, and pigment-based inks. These inks are designed to adhere well to non-porous, smooth surfaces like ceramics, and to resist wear, high temperatures, and chemicals.

Adhesion and Durability: Code needs to be durable to withstand handling, heat (especially if the ceramics undergo firing or thermal treatment), and chemicals used during the ceramic manufacturing process.

Print Quality:

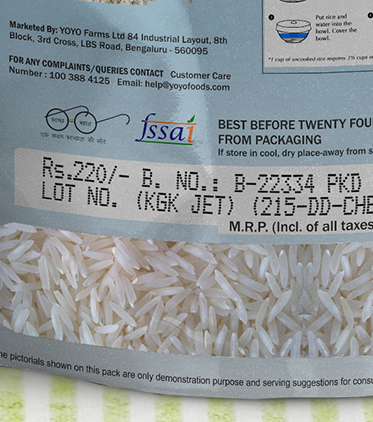

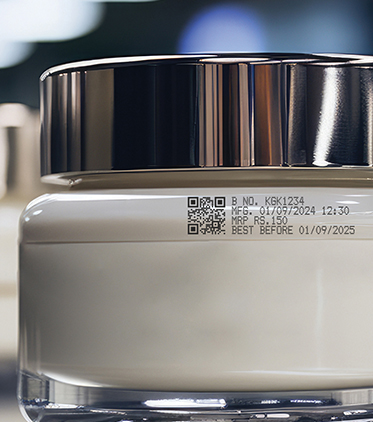

- Long lasting, legible markings such as QR codes, barcodes, and logos can be applied using the CIJ machine.

- KGK Jet has engineered inks for ceramic surfaces, because of their reflective nature, require well-optimized ink formulations for contrast and readability.

Speed and Flexibility:

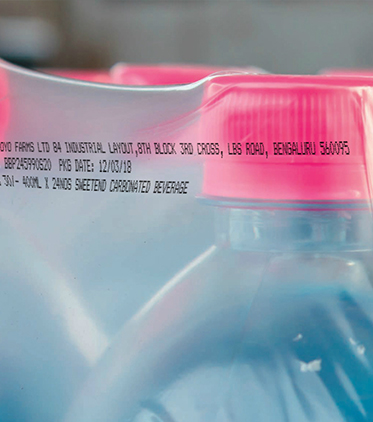

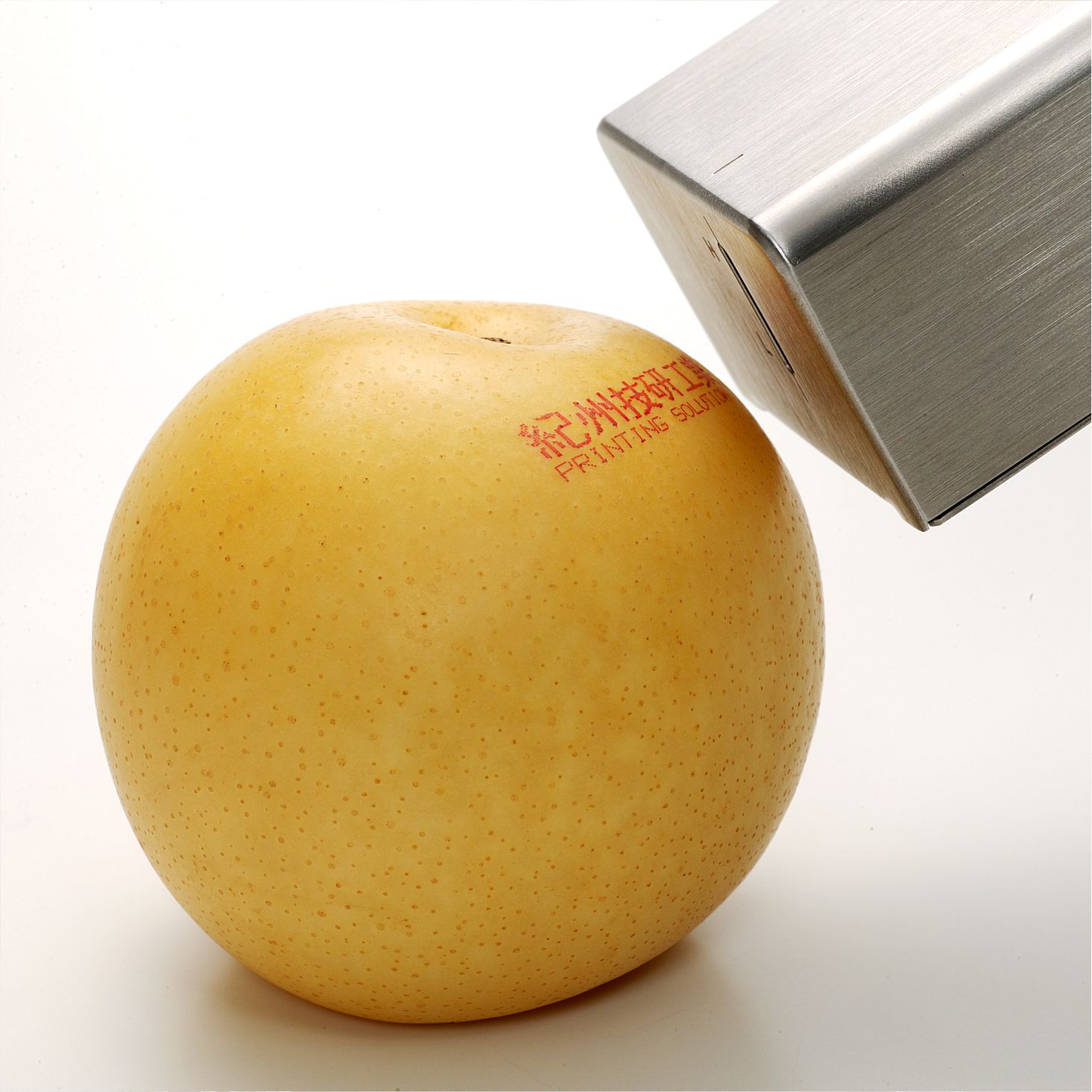

- KGK CIJ machines are known for their high-speed coding capabilities, making them ideal for high-volume ceramic production lines.

- They can be programmed to print varying text, dates, logos, and codes dynamically, which is useful for ceramics that require different markings for different production batches.

Surface Preparation:

The ceramic substrate may require surface cleaning or preparation to ensure optimal ink adhesion, especially if the surface is dusty or contaminated.

Harsh Manufacturing Considerations:

IP 65 Ingress protected machines designed to work in harsh conditions (e.g., heat, dust) often found in ceramic production lines.

If you're using or considering KGK Jet CIJ machines for

marking and coding ceramic substrates, it’s important to work with compatible

inks and ensure proper machine settings to achieve the best results in terms of

print quality and durability.