Coding on Flexible Films and Foil

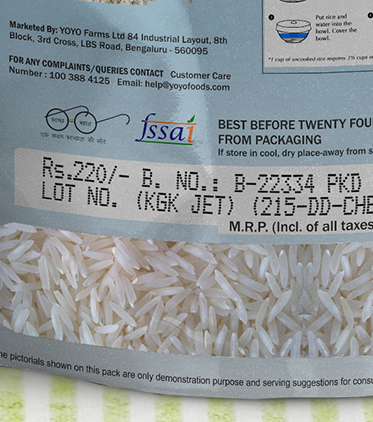

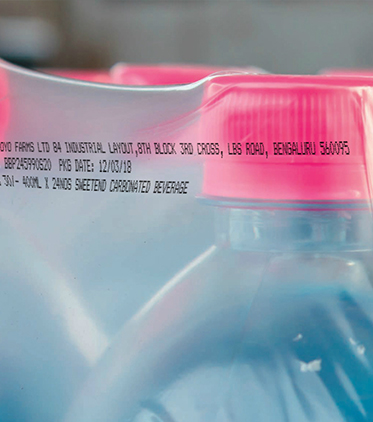

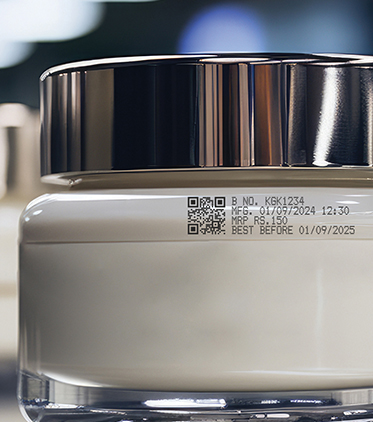

The KGK Jet CIJ (Continuous Inkjet) machine is widely used for marking and coding on flexible films and foils, commonly seen in industries like food packaging, pharmaceuticals, and electronics. This technology is ideal for printing variable data such as batch codes, expiration dates, barcodes, and lot numbers directly onto flexible packaging materials.

Key Features for Marking on Flexible Films and Foils:

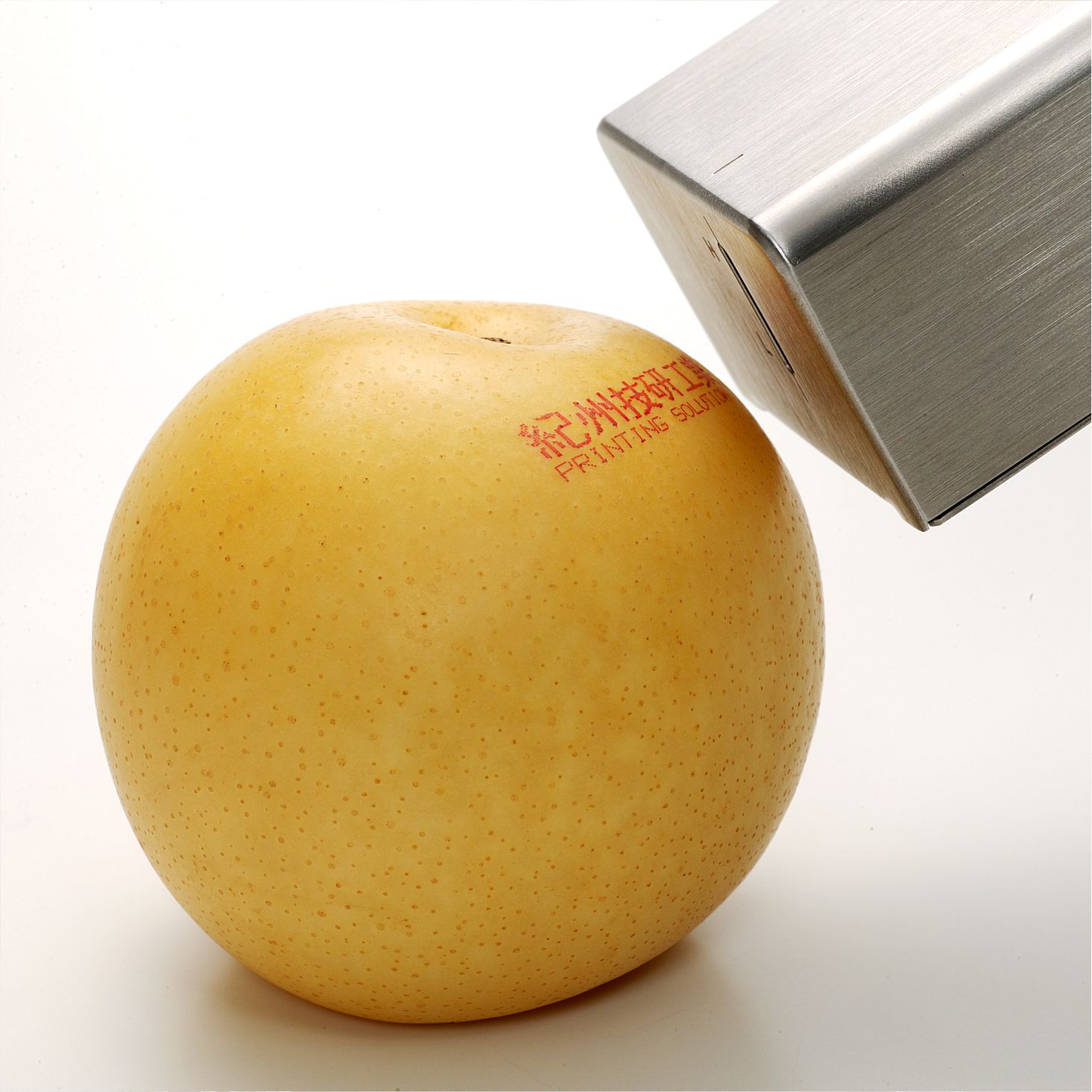

Non-Contact Printing: CIJ technology is a non-contact process, which makes it suitable for printing on delicate and flexible materials like foils and films without damaging them.

High-Speed Printing: KGK Jet CIJ machines are designed to operate at high speeds, making them perfect for fast-moving production lines. They can print clearly on flexible packaging as it passes through the line, ensuring high efficiency.

Wide Range of Inks: The machines support a variety of inks that are compatible with non-porous surfaces like foils and films, including fast-drying and specialized inks for different substrates. Some examples include:

- Solvent-based inks for fast drying.

- UV-curable inks for more robust adhesion.

- Food-grade inks for compliance with food safety standards.

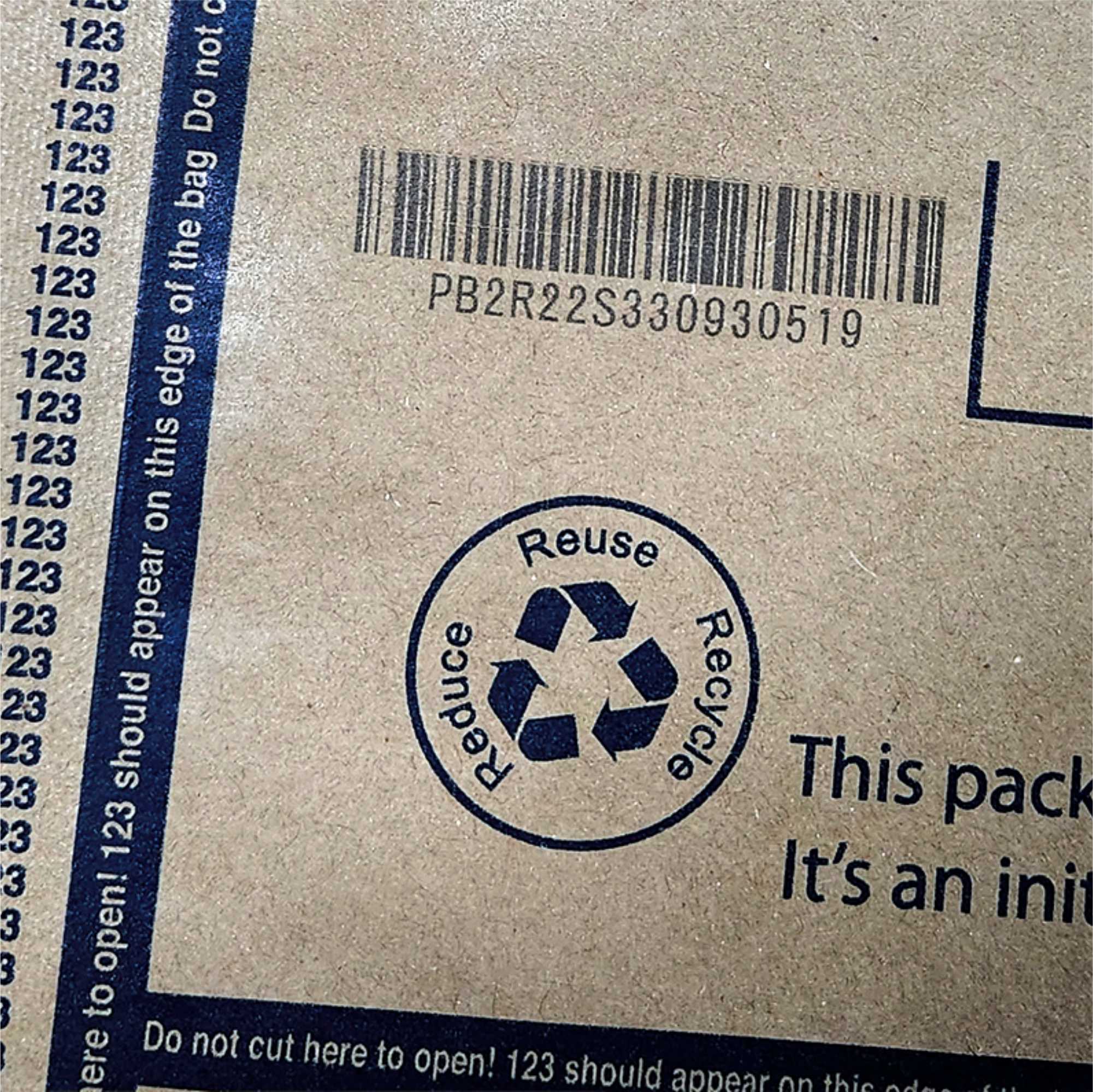

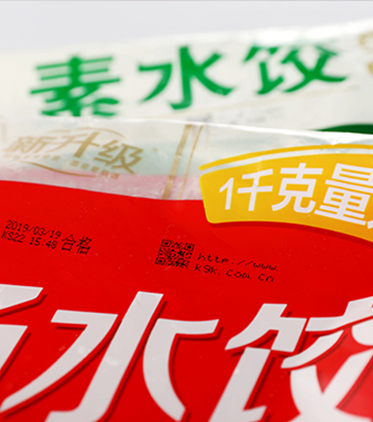

Variable Data Capability: CIJ systems can print variable data such as:

Expiry dates, Batch numbers, Serial numbers, QR codes and barcodes

Printing on Curved or Uneven Surfaces: Due to the flexibility of the CIJ system, it can print on curved or uneven surfaces that are common with flexible films and foils.

Durability and Contrast: The inks used in CIJ are designed to offer excellent adhesion to films and foils, ensuring that the print is durable and resistant to rubbing, heat, and moisture. The print contrast is also strong, making it readable in low-light conditions or through transparent packaging.

Ink Adhesion: Ensuring the proper ink type is crucial for adhesion on materials like foils, especially when packaging is exposed to heat or moisture.

Drying Time: Fast-drying inks are essential for marking on high-speed production lines and preventing smudging.

Cleaning and Maintenance: Nozzle capping save

35% of consumables and regular print-head cleaning time. The Service Management

System sends prior service alerts for preventive maintenance. During

challenging operating conditions, these aid in maintaining consistent print

quality.

The KGK Jet CIJ machine is a great choice for industries where precision, speed, and flexibility are key in marking and coding on flexible films and foils