Print Examiners - PK400

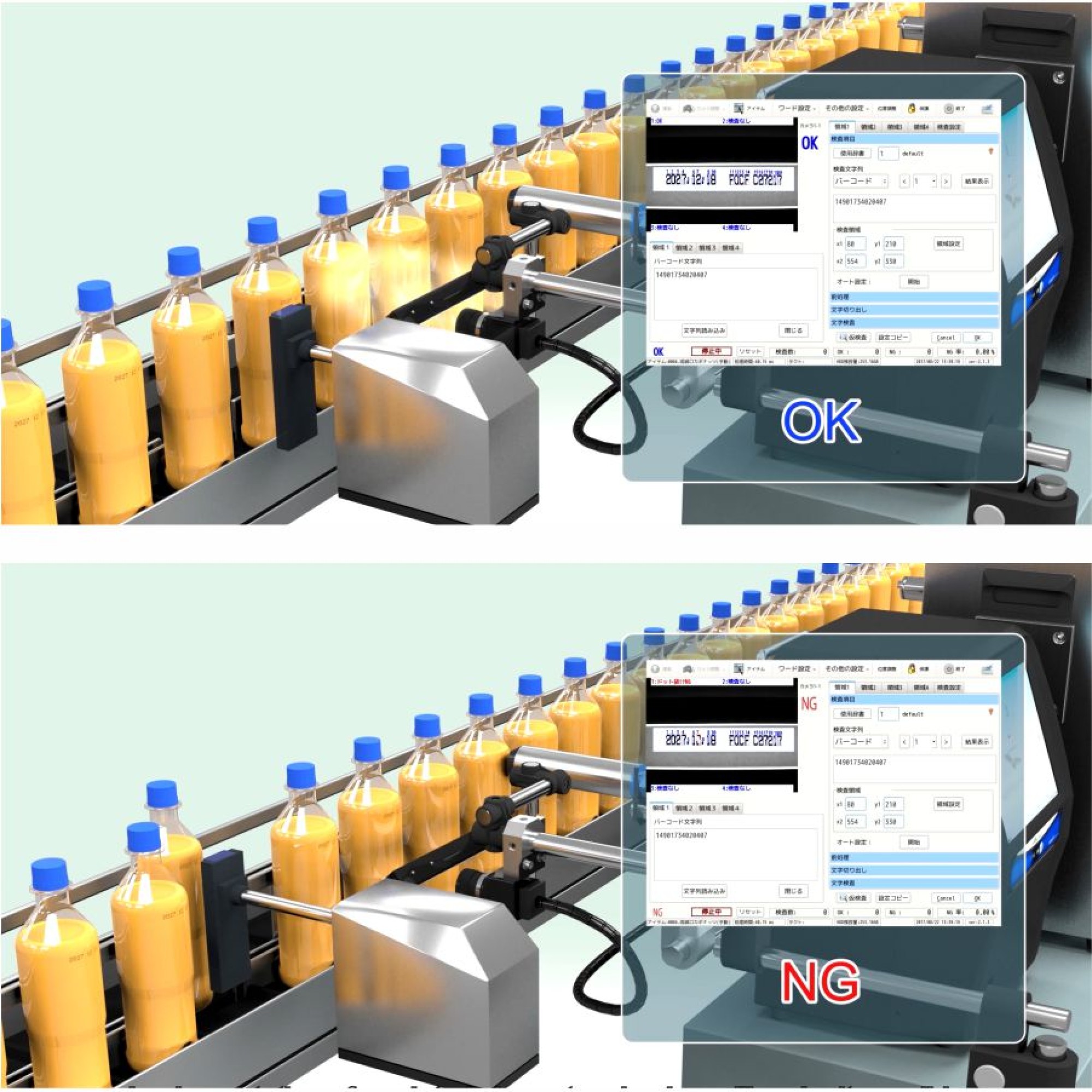

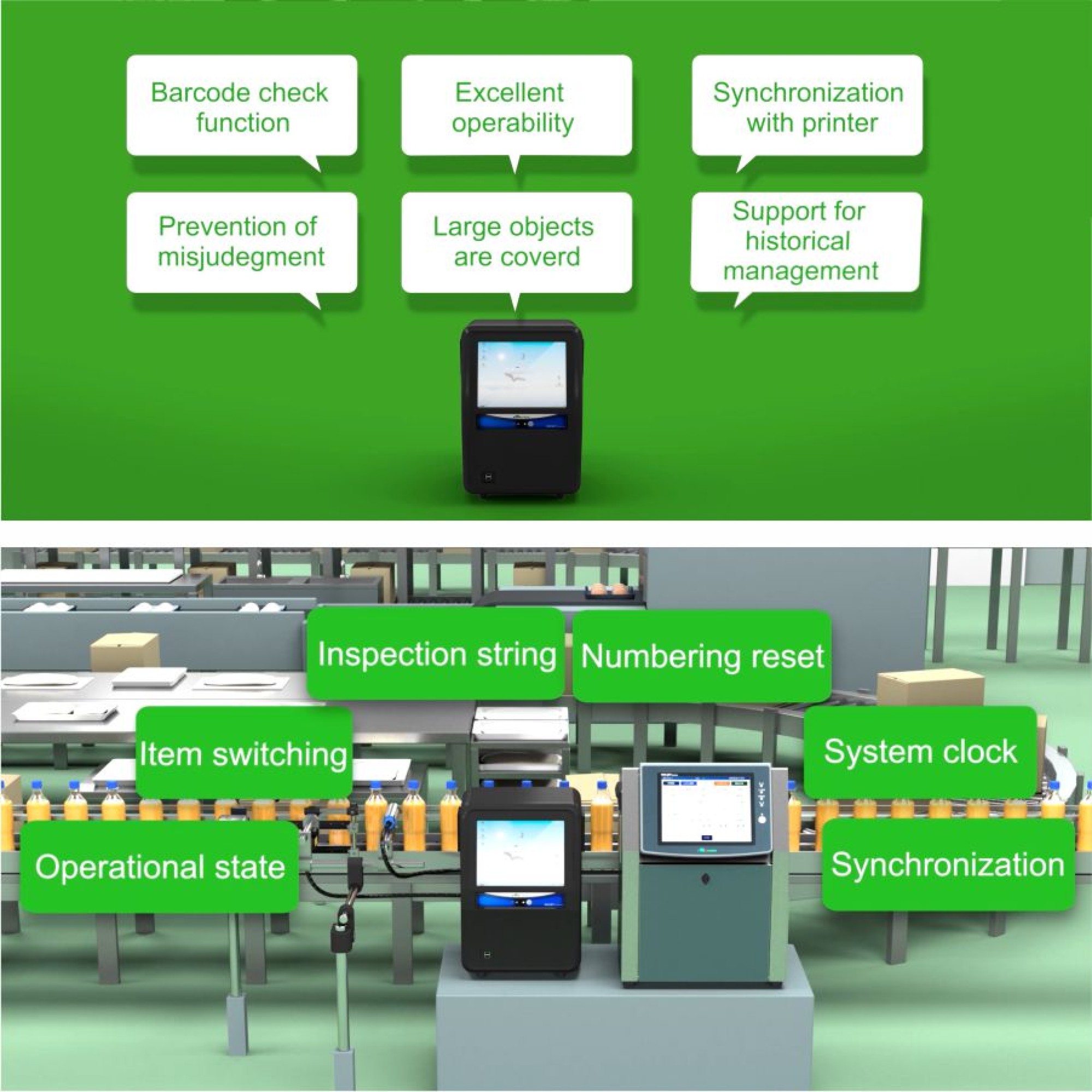

- Barcode is read and compared with text for both barcode quality control and detection of mixed materials.

- Maintains conventional character extraction and matching process while adding a separate quality inspection step.

- Enables strict character quality evaluation without excessively increasing inspection accuracy demands.

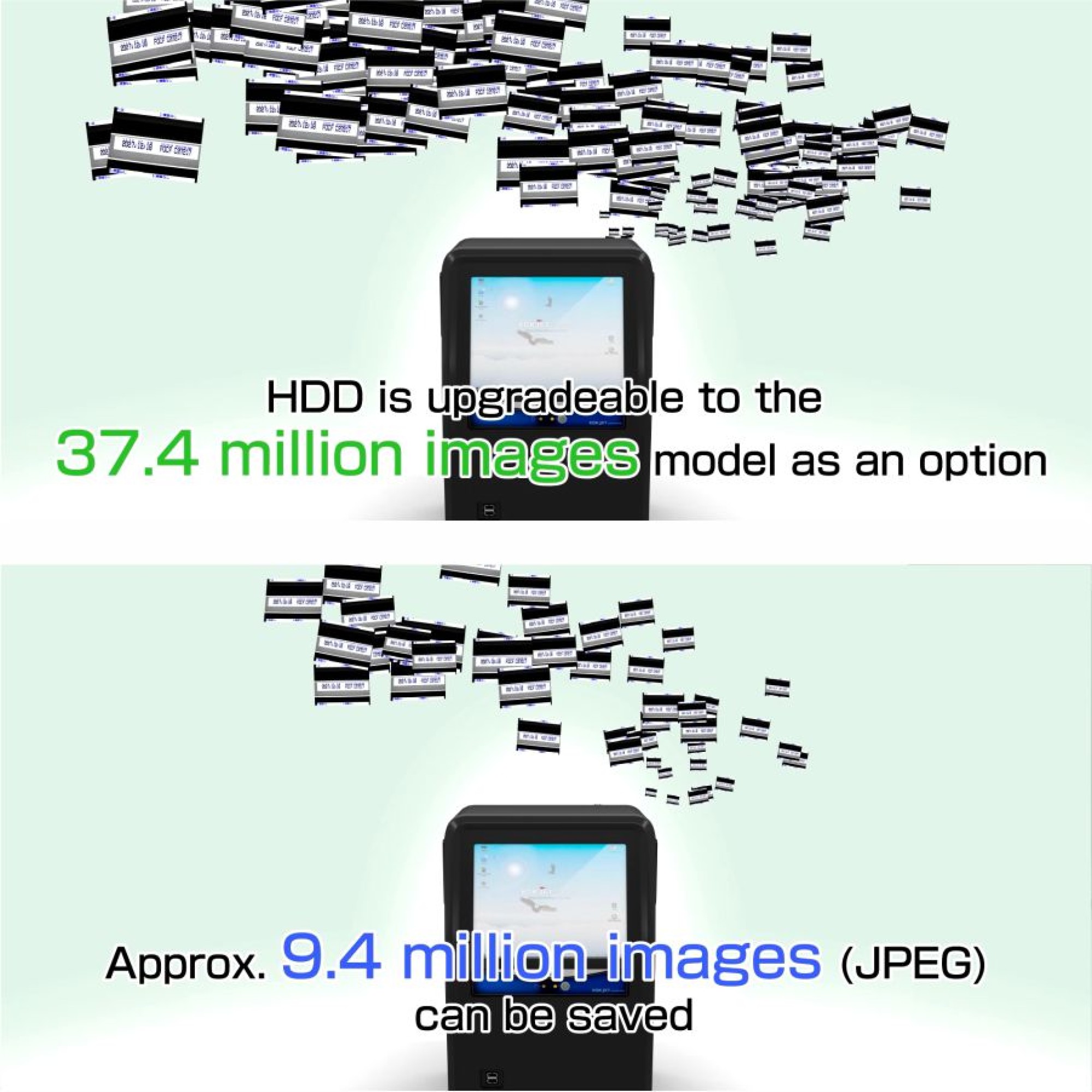

- High availability through data sharing between HDD and SSD ensures system reliability.

- Enhanced maintainability and serviceability support continuous operation, ideal for long-term production lines.

The PK400 Benefits

High-precision print inspection device

Large color touch panel, high operability

- The large 10.4-inch color touch panel makes it easy to find the parameters. In addition, most of the graphical user interface can be displayed on a single screen, allowing for smooth operations.

- By sharing data between two auxiliary storage devices (HDD and SSD), high reliability, maintainability, and serviceability are achieved for continuous system operation.

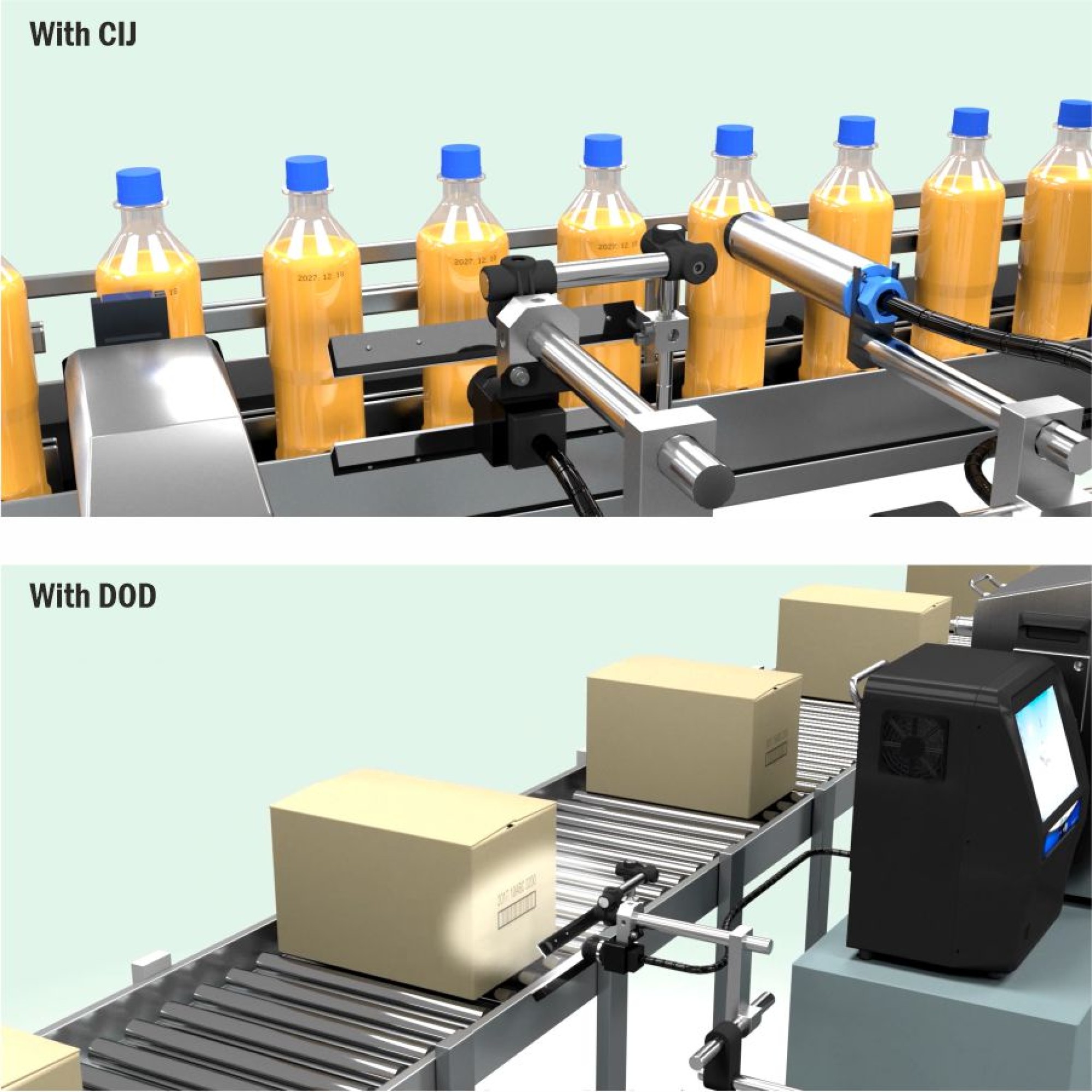

Complements inkjet printers with a wide field of view.

When combined with our inkjet printer, you can use functions such as start/stop, product type switching, inspection string change, numbering reset, and automatic synchronization of the system clock. Not only does it reduce the hassle of operation, it also reduces human errors such as input mistakes.

Samples

Product Specification

|

Model |

PK410 |

|

Number of registered varieties |

Up to 1000 varieties |

|

Number of cameras |

|

|

Camera pixel count |

?Standard camera: 300,000 pixels ?High resolution camera: 5 million pixels |

|

Inspection character type |

Up to 100 alphanumeric characters and other characters can be registered. Other than that, yes or no |

|

Inspection details |

Misprinting, insufficient printing, misaligned printing, tilted printing, presence or absence of printing, missing dots, print density |

|

Number of characters to be inspected |

Up

to 20 characters per area |

|

Date and Time Check |

Compliant with our printer specifications |

|

Numbering inspection |

Compliant with our printer specifications |

|

Character allocation function |

Compliant with our printer specifications |

|

Barcode inspection |

ITF, JAN, CODE39, CODE128, QR, DataMatrix |

|

Mark Inspection |

Pattern matching function using any image |

|

Number of images saved |

?Standard camera: Maximum 18 million images ?High-resolution camera: Maximum 2 million images |

|

Input/Output Signals |

16

inputs: switching types, prohibiting inspection, etc. |

|

I/O |

USB2.0 x 4, RS-232C x 1 |

|

Processing power |

? Standard camera: 70 ms for 10 characters per image ? High resolution camera: 120 ms for 10 characters per image (both vary depending on conditions) |

|

power supply |

AC100V±10P/60Hz 500W *Please contact us separately regarding AC200V. |

|

External dimensions |

300mm(W)

x 261.2mm(D) x 435mm(H) |

|

Operating environment |

5 to 35°C, 20 to 80% RH (no condensation) |

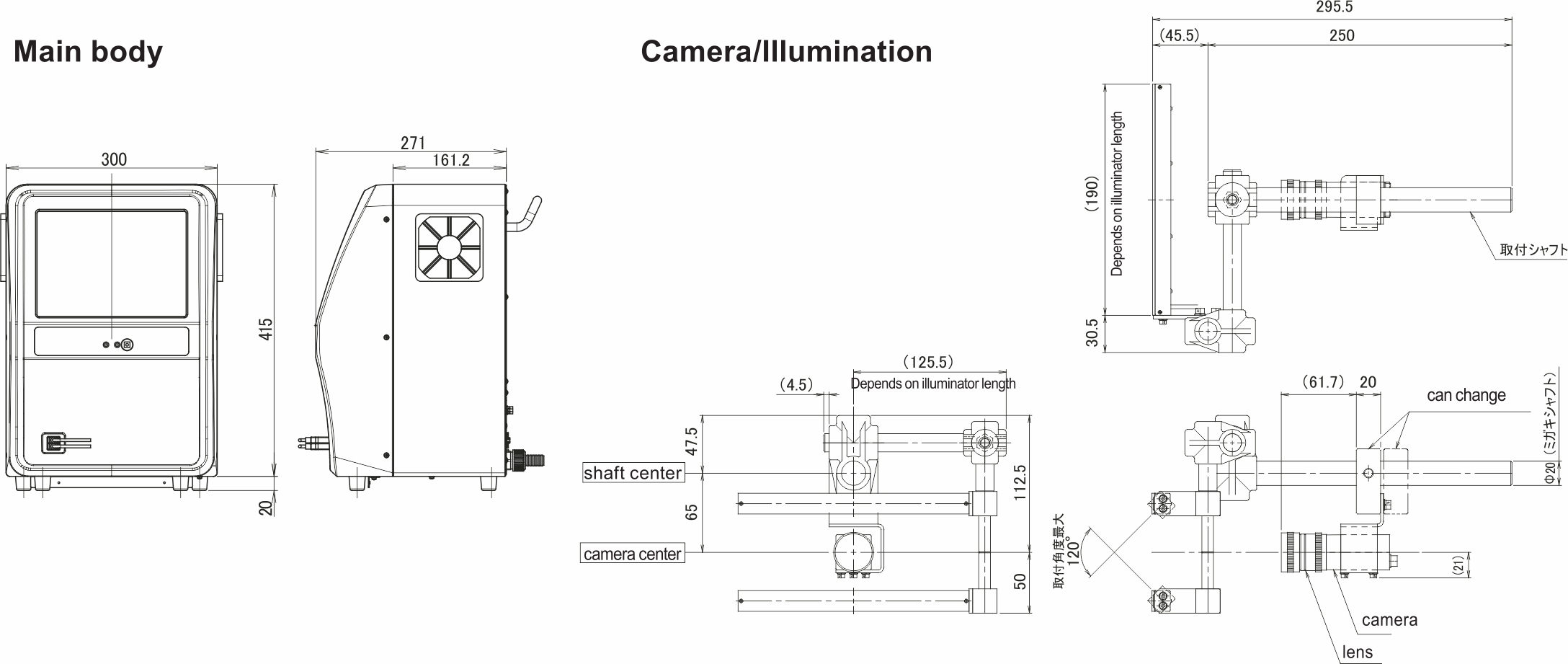

Product Diagram