1968

Producing world's first automatic stamping machine

Before the introduction of this KGK innovation, stamping on the production lines was a manual process. KGK was a pioneer in automating the lines with our self-developed stamping machine, giving us instant success in industrial Japan in the areas of batch number marking and industrial coding systems. With this came the roller coder stamping, which used rubber stamps. KGK has maintained its market leadership in this niche since the introduction of this product and has evolved to be the best industrial inkjet manufacturer (in India and the world.) (Across the globe)

1986

Developing Industrial Inkjet Printers

We thrive in innovating continuously, being agile and responsive to changing times. We developed our continuous inkjet printers (CIJ Printers) coupled with a variety of quick-drying inks that would print on different types of packaging, including PE PP PET HDPE LDPE plastic bottles or any material. Regardless of substrate nature or quality, our high- grade Piezo-style continuous inkjet printers could print brand names, logos, images, various barcodes and QR codes in addition to best-by dates and lot numbers on the packaging. This helped revolutionise the concept of customer empowerment and added value to business operations. We also developed Drop on Demand Printers (DOD printers), thermal inkjet printers (TIJ printers) and high speed inkjet printers for batch coding.

2002

Developing Specialty lnks

Articles requiring characters printed from industrial inkjet printers can be extensive, including everything from cardboard to metal, plastic, ceramic and foodstuff. Each substrate has unique needs, quality and performance requirements. We started developing our ink materials and established the Ink Development department for the development of unique inks based on different market needs and to respond quickly to requirements. In addition to regular inks, we also have UV Ink, Stealth Inks, and Edible inks for printing characters directly onto foodstuffs like eggshells and fruit, and tablet Inks for printing characters onto medicinal tablets. Our inks ably complement the coding, marking and labelling needs of our clients by working in tandem with our industrial inkjet printers to deliver the highest possible value for money.

2002

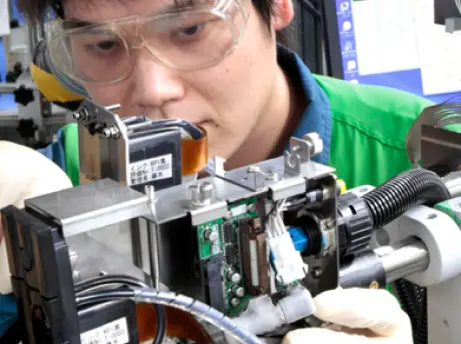

In-House Development of High-Precision Heads

In addition to the Ink Development Department, we established the Print Head Department in 2002. We became the only inkjet printer manufacturer to regulate everything from 'development to production' in-house, including ink and the inkjet's indispensable head. With a depth of know-how in high precision micro-processing technology, we have been developing heads to match client needs. Our expertise in industrial inkjet printing has helped us innovate and create suitable print heads for the printing needs of niche industries, including electronics.

2006

Creating Further Trust with Character Inspection Equipment.

We started developing inspection systems as an OEM to achieve higher customer delight. We aimed to create an inspection system that would help us leverage our know-how of inkjet printer manufacturing to the fullest. In 2006, we established the Image Recognition System Development Department. Our efforts have led to the development of inspection systems that was not only robust and reliable but also user friendly and intuitive.

2013

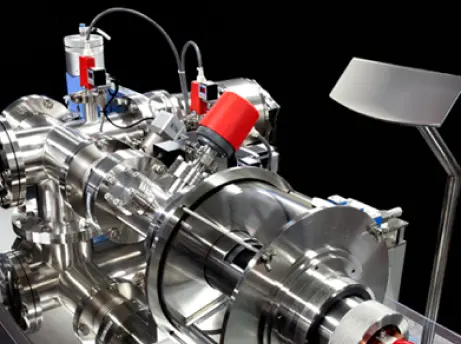

New Challenges Overcome

Initial production of metal nano particles for both wet and dry processes as well as inkjet ink utilising metal nanoparticles was a huge success. It reinforced our position as a leading industrial inkjet manufacturer and service provider. Subsequently, we started testing in the area of Printed Electronics, developing our inkjet system to suit wiring and electronic circuits. We evolved further to offer complete inkjet systems to match a great variety of customer demands from the trial manufacturing of various metal nanoparticle inks to graphing systems.

2019

Founder Awarded Prestigious Kyokujitsutankosho

on 21st May 2019, for his outstanding contribution to "The growth of Wakayama prefecture and Japan's economy", our founder was awarded the Kyokujitsutankosho award.

The award was enacted in 1887 as Japan's first medal. The design of the medal is arranged with rays centred on the Rising Sun, with rose flower leaves. Kyokujitsutankosho is given to those who have outstanding achievements in each field, and we continue in our mission to deliver the best industrial inkjet printing and ink solutions to the world.