Print Examiners - PK100

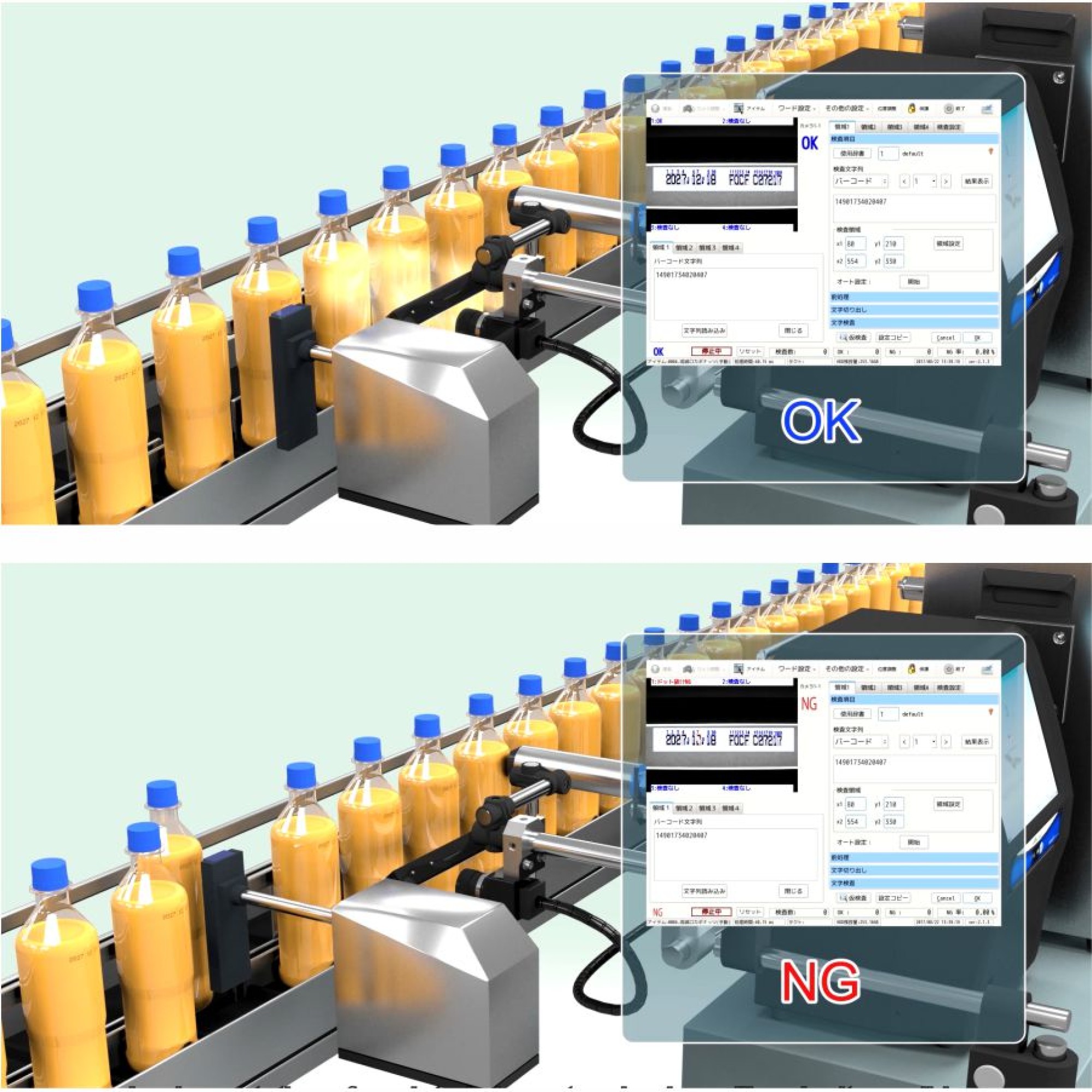

- KGK Jet PK100, inspection settings can be displayed on a single 8-inch monitor screen, empowers you just see the device settings at a glance.

- Store up to 1.8 million images by combining it with the separately generated history file to enhance traceability.

The PK100 Benefits

Full-scale print inspection with simple operations

Just circle the printing area with your finger on the touch panel. Able to store 1.8 million inspection screens

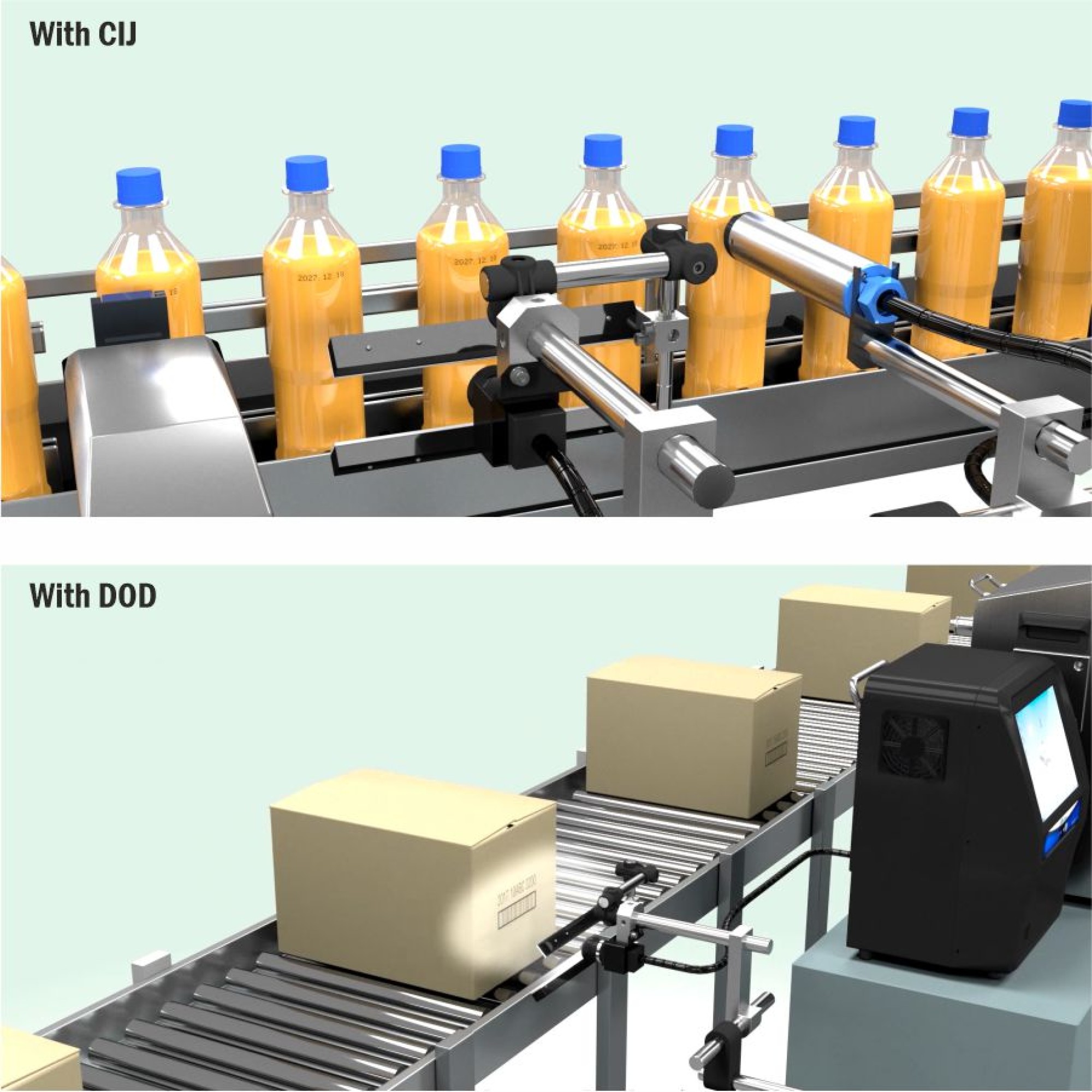

Space-saving installation

No need to install in a control panel or prepare a separate DC power supply

Synchronization

By using the synchronization function, not only can you reduce the time and effort required for setting operations, but you can also reduce human errors such as input mistakes.

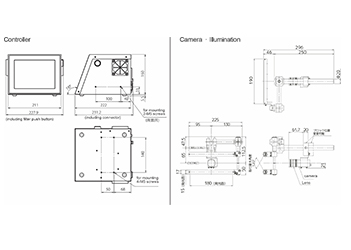

Product Specification

|

Model |

KGK JET CHECKER PK100 |

|

Number of registered varieties |

Up to 20 varieties |

|

Number of cameras |

1 piece |

|

Inspection character type |

Up to 30 alphanumeric characters and other characters can be registered. Other characters are not available. |

|

Inspection details |

Misprinting, insufficient printing, misaligned printing, tilted printing, presence or absence of printing, missing dots, print density |

|

Number of characters to be inspected |

Up

to 20 characters per area |

|

Date and Time Check |

Compliant with our printer specifications (year/month/day) |

|

Character allocation function |

Compliant with our printer specifications |

|

Number of images saved |

Up to 1.8 million images (JPEG images) |

|

Input/Output Signals |

16

inputs: switching types, prohibiting inspection, etc. |

|

I/O |

USB2.0 x 2, RS-232C x 1 |

|

Processing power |

100 ms for 1 image, 10 characters (varies depending on conditions) |

|

power supply |

AC100-240V ±10P/60Hz 80W |

|

External dimensions |

227.9mm(W)

x 231.2mm(D) x 165.5mm(H) |

|

Operating environment |

5 to 35°C, 20 to 80% RH (no condensation) |

Product Diagram