Coding on Rigid Containers

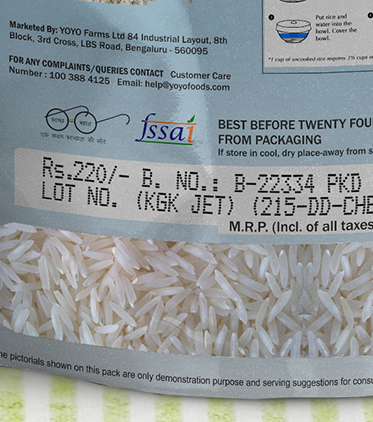

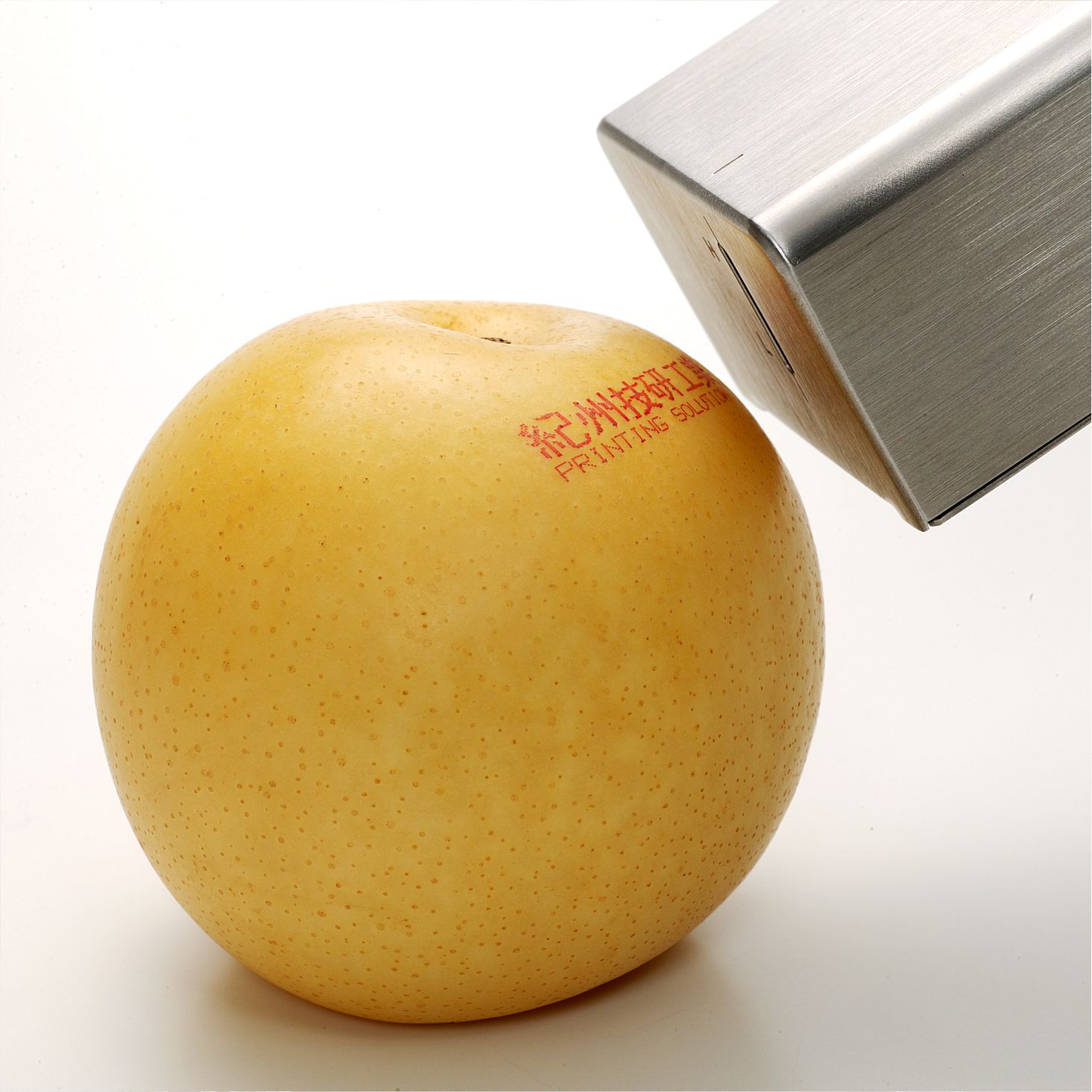

A KGK Jet CIJ (Continuous Inkjet) machine is used for printing or marking on various types of surfaces and materials, including rigid plastic containers. CIJ technology works by propelling tiny droplets of ink onto the surface of an object as it moves through the production line, allowing for non-contact, high-speed marking.

Here’s a breakdown of how it applies to marking on rigid plastic containers:

Non-Contact Printing: Since CIJ is a non-contact process, it can print on irregular, curved, or rigid surfaces, which makes it suitable for rigid plastic containers.

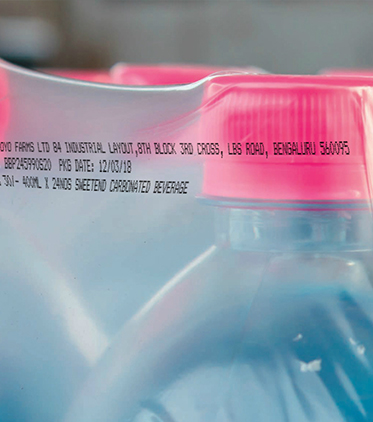

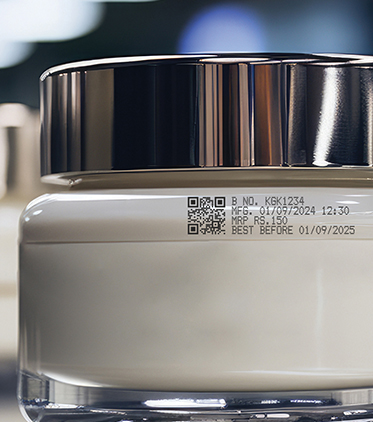

High-Speed Operation: CIJ is ideal for fast-moving production lines, such as those used in packaging rigid plastic containers for products like beverages, chemicals, and cosmetics.

Material Compatibility: The CIJ machine can print on a wide range of plastic materials, including polyethylene (PE), polypropylene (PP), and PET (common in rigid plastic containers).

Durability: The inks used in CIJ printing are generally resistant to wear, UV exposure, and chemical reactions, ensuring that the markings last through handling and shipping.

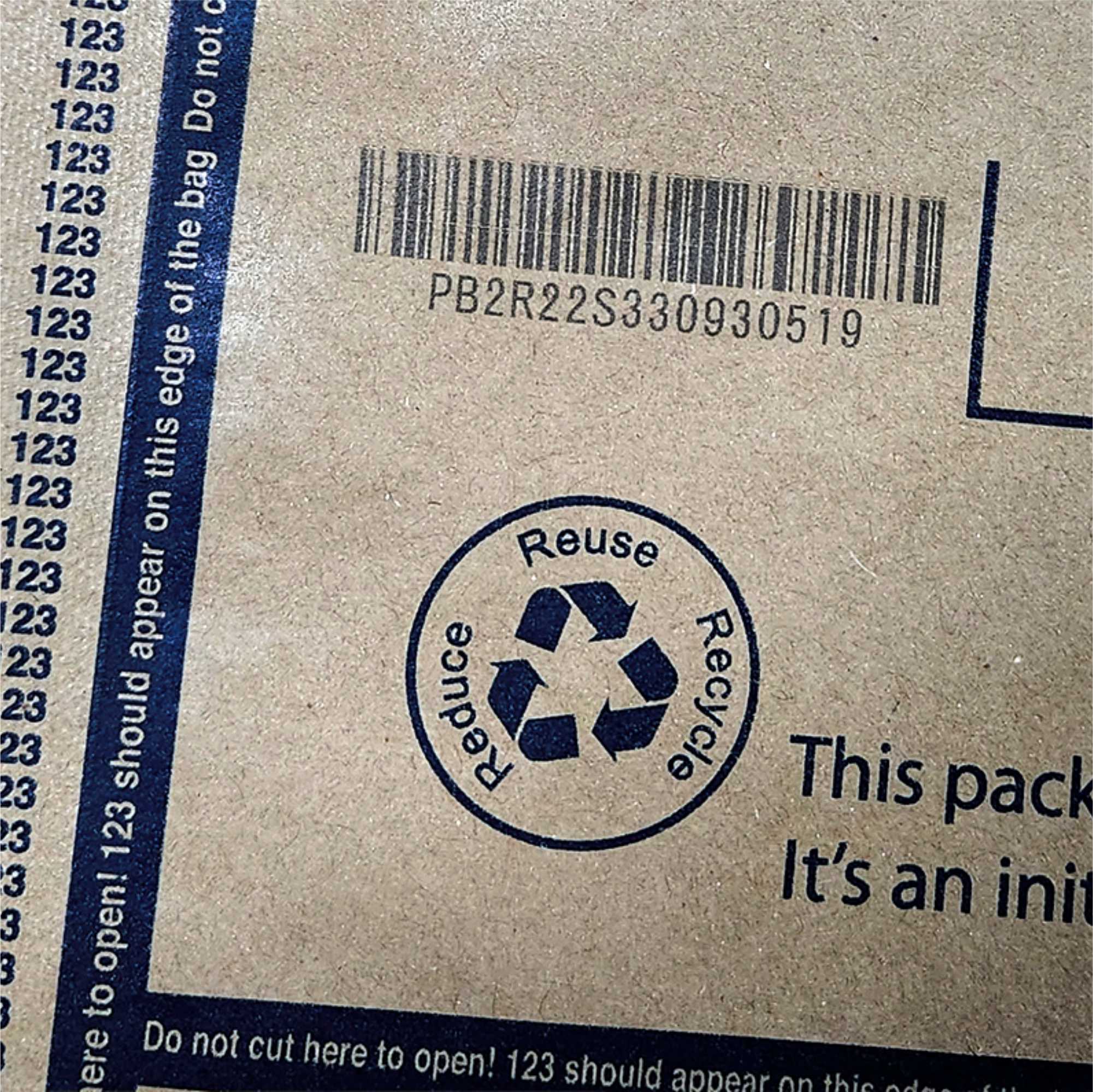

Applications: CIJ marking is commonly used to print expiration dates, batch numbers, barcodes, and product identifiers on rigid plastic containers.

Would you like more technical details or information on specific KGK Jet CIJ models?