How KGK Jet CIJ machine help Cable, Wire and Pipe manufacturers to increase production.

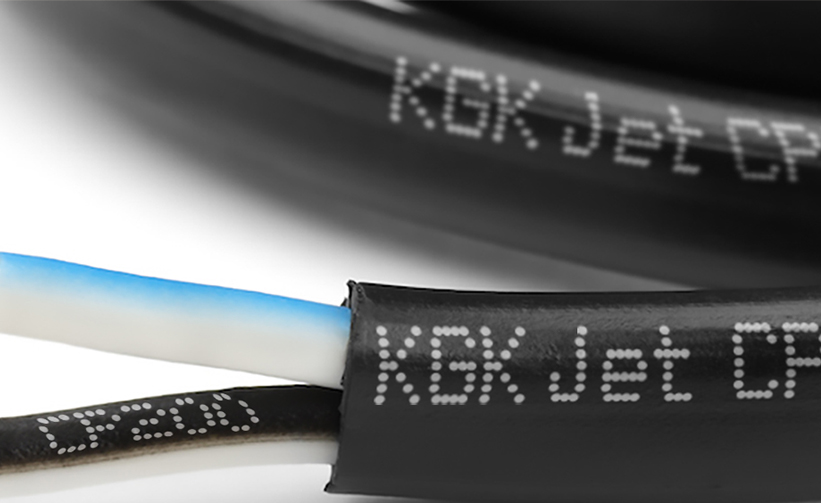

KGK Jet Industrial Inkjet coding solutions ensure that logo, text & cable specification marking are legible, offers precision with high reliability even at high speed, using our reliable meter marking solution without even touching the substrate.

KGK Jet understand the challenges of Cable & pipe manufacturing industry like high input cost, verity of substrate, high temperature working environment and High-speed non-stop manufacturing. You need Pipe Printing machine solution which has absolutely no downtime as well as negligible waste.

Our PVC Pipe Printing machine delivers maximum productivity without downtime. Japanese technology with over 50 years of expertise in marking & coding solution entrusted by our customers across cable & pipe manufacturing industry.

KGK Jet machines delivers legible & precision coding even on substrates like PVC, PTFE, XLPE, ETFE, FEP, EPDM and HDEP. Due to low surface energy these substrates have difficulty in bonding with inks. KGK jet Cable Printing Machines use “integrated in-line plasma treatment” to improve surface adhesion.

The plasma provide heat which create space between substrate molecules enabling ink molecules to bond indelibly.

The Meter-Marking Software is one of the most reliable feature in our PVC Pipe Printing machines. KGK Jet Cable Coding machine connected with the encoder calculate the speed

for desired logo coding, exactly after every prescribed interval.

The inks produced by KGK Jet Pipe Printing Machine have a varied range resulting in better printing on the required substrate. The quick dry ink enables high speed winding and

rewinding on cable bobbins without worrying secondary print transfer. KGK Jet inks are highly resistible to environment elements like dust, sun light and water.

Also available in various colours to suit customer requirement.

Need some more information or ideas?

Get in touch with us (hyperlink to contact us page), and our expert team will answer your queries and help unlock business value by using our KGK Jet Pipe Printing Machines

Subscribe to our newsletter and receive a selection of cool articles every weeks

The Latest

Tough Environments Strong Codes KGK Jet CIJ and Laser Printers for Agrochemical Packaging

13 October 2025

![]() 2 minute read

2 minute read

How KGK Jet CIJ and Marking Laser Technology Stay Aligned with Food Packaging for Products with Short Shelf Life

11 September 2024

![]() 2 minute read

2 minute read