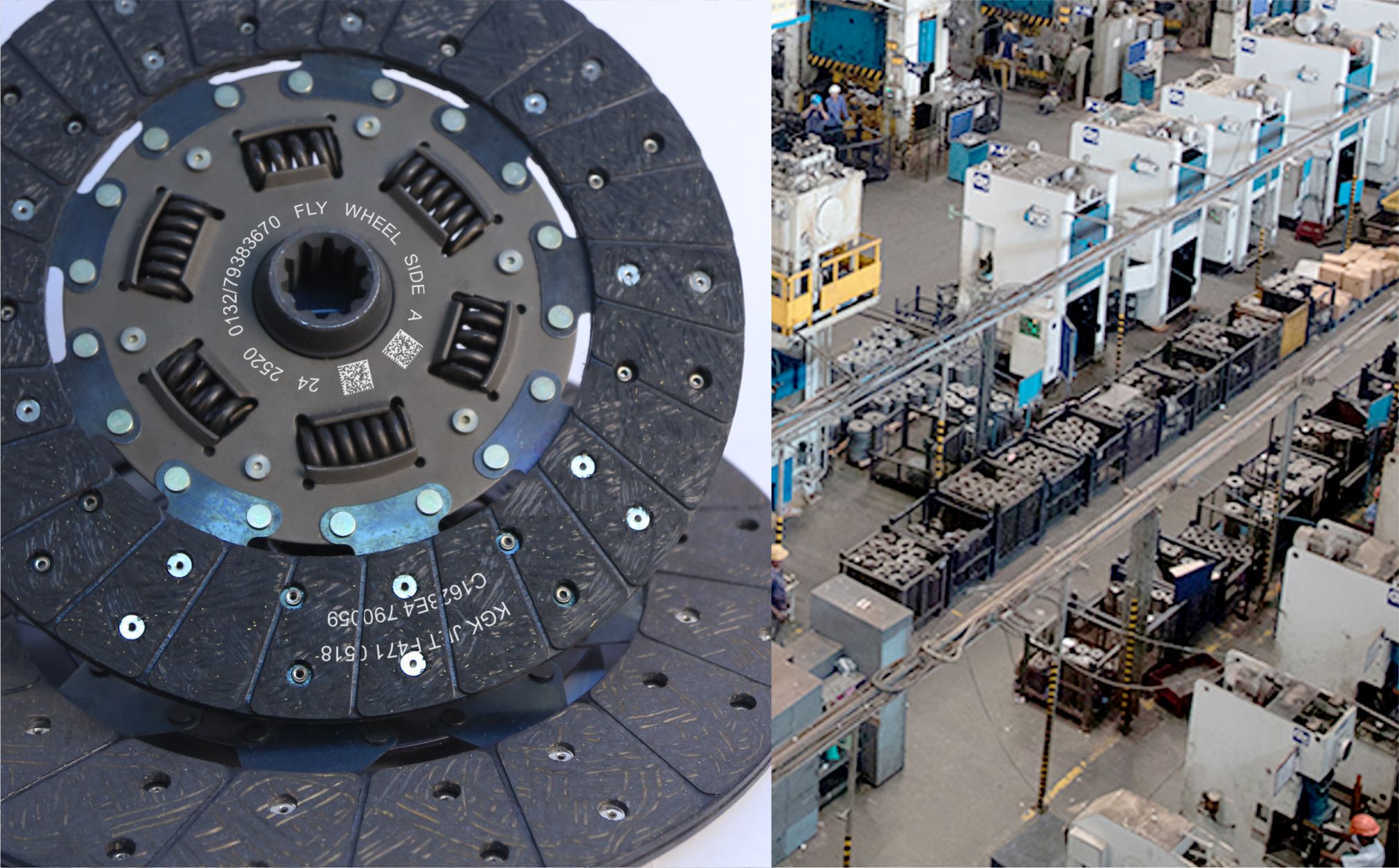

Automotive Find Batch Coding Solution with KGK Jet for Special Application.

Company Profile: A global supplier of automotive spare parts needs to ensure traceability by printing codes directly on the products.

Challenges & Opportunities:

Mandatory Coding: For traceability purposes, the

customer has specified that two lines of batch codes must be printed on the

automobile clutch plate.

Substrate: The surface of the clutch plate, being

dark, smooth, and non-porous, created distinct challenges for marking and coding.

Harsh Manufacturing Environment: The

manufacturing environment contained residues of oil and grease used in the

assembly of finished products. All ink and coding equipment needed to undergo a

corrosive-resistant oil and grease test as specified by the customer.

Software Integration: To monitor the production

customer were using Lab View software, any marking and coding equipment need to

be seamlessly integrated with customer software.

Economical Cost: As a process customer’s purchase

team was evaluating multiple competition machines. Their expectation was lower

running cost with quick service support.

Ink procurement - limited timeframe: With the

automobile industry's focus on Just-in-Time (JIT) inventory management, which

prioritizes minimal inventory levels, KGK Jet needs to ensure quick delivery of

consumables and spares within a short period.

KGK Jet Solution

CIJ with Traversing System: A customized

traversing system was used with the KGK Jet CCS-R printer, fitted with a

50-micron nozzle and CP247 high-contrast white ink, to allow the printhead to

move over the circular clutch plate for printing a two-lines of batch code.

Robust Design: Robust & versatile keyboard

and screen design proves operators friendly in daily operations.

Harsh Manufacturing Environment: The KGK

Jet CIJ Auto Start-Stop, along with its Positive Air and Nozzle Capping

technology, ensures clear coding even in challenging manufacturing conditions.

The Service Management System (SMS) notifies customers before each service.

Customers appreciate how these features of the KGK Jet CIJ machine enhance

performance and efficiency.

Key benefits of CCS-R:

Simple, Efficient and Stable: Freedom to edit 1

to 4 lines of text, serial number, linear bar code, as well as graphics and

logo.

Sturdy Nozzle Head: To enhance work efficiency,

printhead has been designed for quick changeover between lines and can operate

in a smaller space.

Built for rugged use: Keyboard & screen is built

to be highly responsive and accurate, while also providing a longer lifespan.

Key Reasons for Choosing KGK Jet:

- KGK

Pan India installation & team in-depth knowledge of the industry.

- Ink

manufacturing facility in India for product pre or post-sales

support.

- Integrating

KGK solution without disturbing existing production line.

- Quick

& proficient service team who responds to 24x7 customer

queries.

- Our

Japanese DNA for continuous research & improvement of product &

services.

Objectives:

- Customer

is operating CIJ machines successfully for last 3 years, integrated well

in existing production.

- Achieve

100% uptime with KGK Jet's on-site service support, complemented by SMS

for proactive preventive maintenance.

- Reducing

ink and consumable costs accelerates the customer's return on investment.