Finnish Mobile Charger Maker Leverages KGK Jet to Improve Coding Adhesion

Company Profile: Finland based manufacturer of power supplies for mobile and other electronic devices in Chennai. Customer required to print data matric 2D machine readable code on components for inline product identification

Challenges & Opportunities:

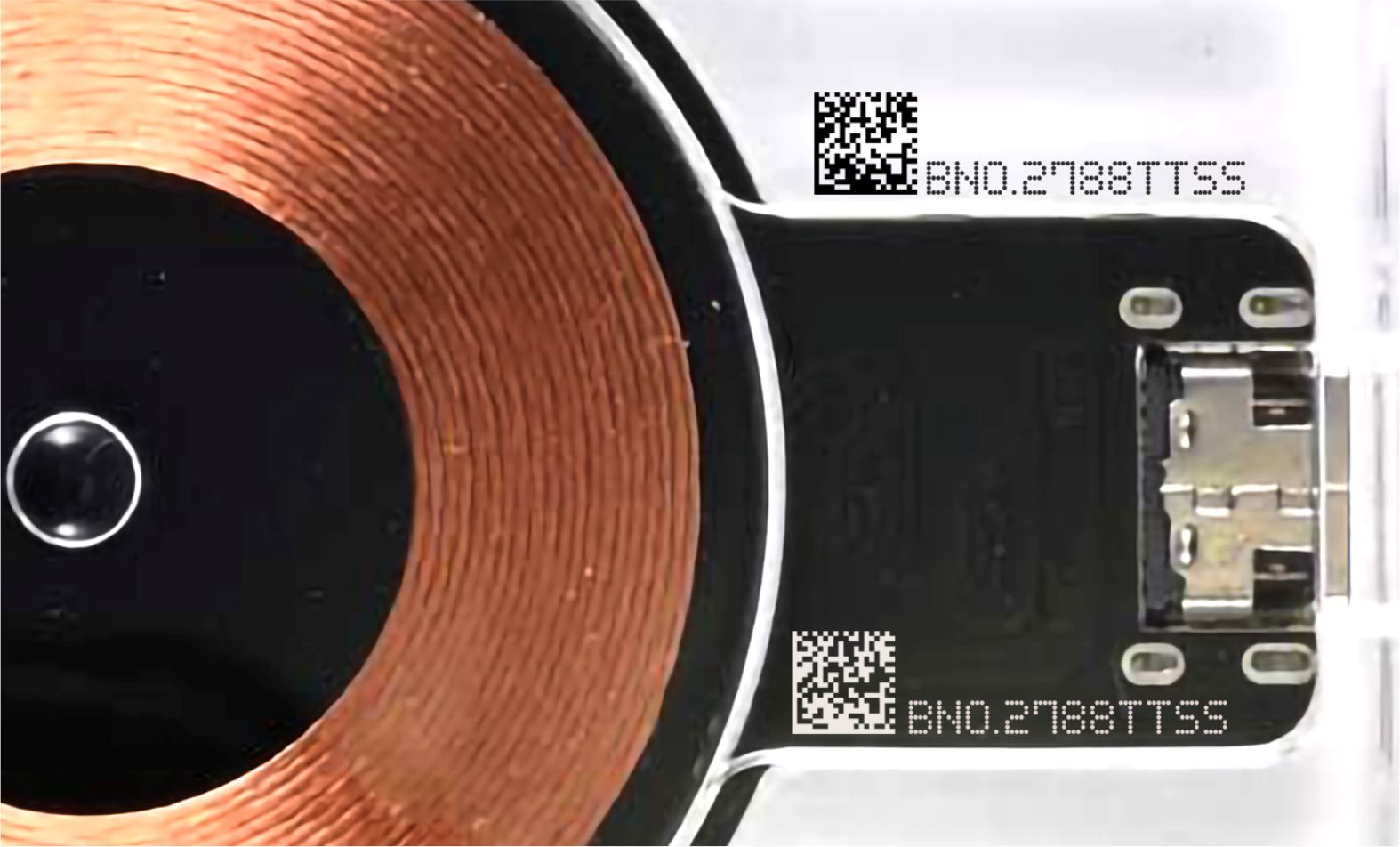

Data matrix code: 6mm 2D code on various components for internal product identification

Adhesion issues: Substrate of component was rigid and transparent which proves challenging to withstand print.

Software integration: The coding machine must be integrated with a vision system to ensure precise quality inspection. Furthermore, it should interface with customer software to create a unique data matrix code that the coding machine will print.

Fewer supply chain disruptions: The manufacturer of coding machines expected to keep just in time ink inventory and a dedicated support team on standby, ensuring continuous production.

KGK Jet Solution

New Ink Development: KGK Jet recognized the need for specialized inks tailored for customer various substrates. To meet this demand, KGK Jet Japan Research & Development Center developed three pigment inks: CP940 Black, CP243 White, and CP271 White, specifically designed to serve customer needs.

High Speed coding: Designed to code up to 4 lines, the CCS3000L CIJ machine has IP54-rated ingress protection and a fluorine-coated nozzle to prevent contamination, ideal for high-speed continuous production environment.

High Speed Scanning: The customer’s vision system consistently read the data matrix code printed with KGK Jet's specially formulated pigment inks, ensuring flawless quality inspection.

Flowless Integration: CCS3000L was integrated with vision system & customer software using LAN port.

Reliable performance: The CCS3000L utilizes positive air pressure within the print head to keep out dust and moisture. Its innovative nozzle capping technology protects the nozzle when the printer is idle, preventing ink contamination and reducing maintenance, allowing for prolonged, uninterrupted production.

Top-Notch Support Services: KGK Jet service engineers were highly responsive during the demonstration, making necessary adjustments during installation and addressing all inquiries promptly. In addition, KGK Jet CIJ machines are equipped with a Service Management System (SMS) that facilitates preventive maintenance, helping to reduce breakdowns and improve efficiency.

Key benefits of CCS3000L

High Speed Coding: New print-head design (P-type) for high-speed & legible 4 lines of coding. Also equipped with Fluorine coated nozzle, which protect print-head from contamination.

Multi-control support: Multi-control (slave function) allows one master unit to control up to 16 units.

Tailor-Made intelligent data communication: Easy integration with a customer ERP system or database can be achieved with the use of customised special integration software to facilitate continuous and batch production.

Key Reasons for Choosing KGK Jet:

- The KGK Jet manufacturing site in India is vital for the swift availability of consumables and spare components.

- KGK Jet specializes in dedicated ink research and development, offering a unique blend of machine and ink manufacturing.

- Team in-depth knowledge of the industry and addressing the key pain area during evaluation.

- Quick & proficient service team who responds to 24x7 customer queries.

Customer Benefits:

- With the integration of KGK Jet technology, customers achieve reliable 24x7 the ability to produce without interruption.

- The customer receives coding that meets their global quality standards.

- KGK jet guarantees the highest quality coding, achieving 100% scannable machine code as required by customers.