Abrasives Manufacturing Experience KGK Jet Batch Coding Technology

Company Profile: Produces high-quality material solutions, including abrasives, electrominerals, ceramics, refractories, and energy storage materials.

Challenges & Opportunities:

First Requirement:

- Customer is using stencil for print on the abrasive wheel (Porus Surface)

- Single-color printing (2-3 lines) will be done in a radius, with a print height of 70 mm on the abrasive wheel.

- There will be software integration with the customer's ERP system to facilitate the printing of messages.

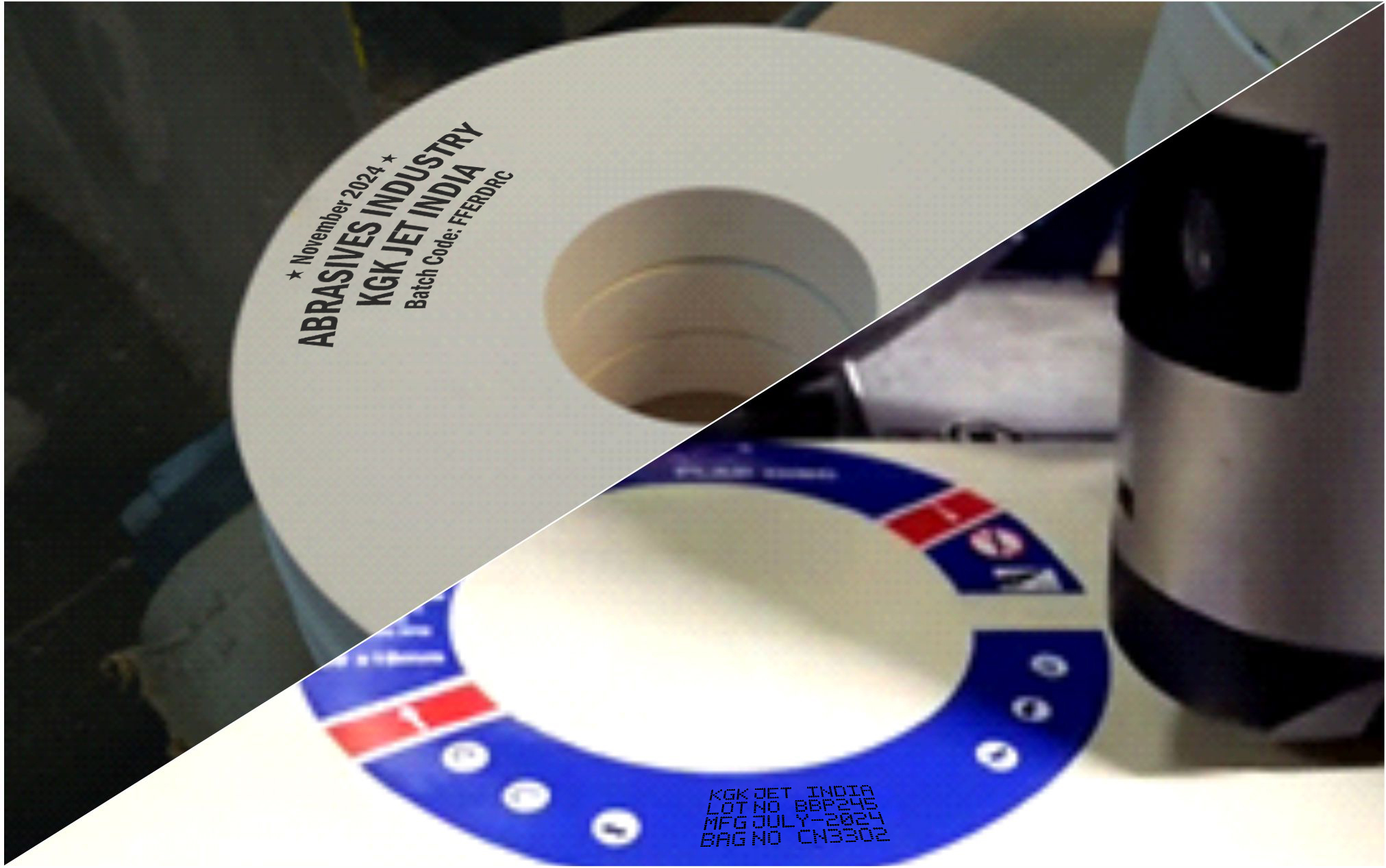

Second Requirement:

- Customer need 3-line black print on laminated labels, using auto feed label machine.

KGK Jet Solution

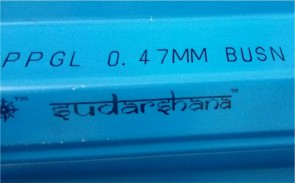

For direct printing on Abrasive Wheel

HQ8500 DOD machine: KGK Jet recommended HQ8500 Controller and Print Head S510 for 70mm

Print Height: HQ8500 with S510 print head capable to print 70mm height with 180 DPI resolution with print head moving with X & Y Axis’s for coding.

Versatile controller: Window based HQ8500 controller is capable to integrate with customer ERP message with speed upto 67m/min.

For direct printing on Laminated Label

CCS3000L: KGK Jet recommended CCS3000L 4-line coding machine to coding on laminated labels.

Integration: CCS3000L matched the auto feed label applicator speed, to aid high production volume.

Key benefits of HQ8500:

- Print height from 1mm to 3mm, Print speed upto 67 meters/min

- Store message up to 10000, option of Horizontal & Downward directional print.

- The nozzle arrangement is one row, which prevents printing from being disrupted by speed changes.

- Change in print speed won't affect the print because of the one row nozzle arrangement.

- The use of oil-based ink prevented nozzles blocking.

- Printing of various barcodes including barcodes and QR codes is possible

Key benefits of CCS3000L:

- High speed coding: New print-head design (P-type) for high-speed & legible 4 lines of coding. Also equipped with Fluorine coated nozzle, which protect print-head from contamination.

- Tailor-Made intelligent data communication: Easy integration with a customer ERP system or database can be achieved with the use of customised special integration software to facilitate continuous and batch production.

- Stable coding even in humid and dusty environment: Positive air pressure inside the print-head, keeps dust and humidity out, resulting in no contamination of head and ink. IP54 protected CCS3000L print head need not clean before every start & stop.

Key Reasons for Choosing KGK Jet:

- Ink manufacturing facility in India for product pre or post-sales support.

- Integrating KGK solution without disturbing existing production line.

- Quick & proficient service team who responds to 24x7 customer queries.

- Our Japanese DNA for continuous research & improvement of product & services.

Customer Benefits:

- Customer saving on Time & labour cost as pint directly on substrate.

- Freedom to edit and store message improved productivity

- Crisp & precise coding enhance customer brand vale.