Steel Maker Enhances Sheet Manufacturing with KGK Jet Coding Machine Technology

Company Profile: Manufactures and distributes steel products. The Company offers rolled and coiled steel, sheets, aluminum foil, pipes, and other steel products.

Challenges & Opportunities:

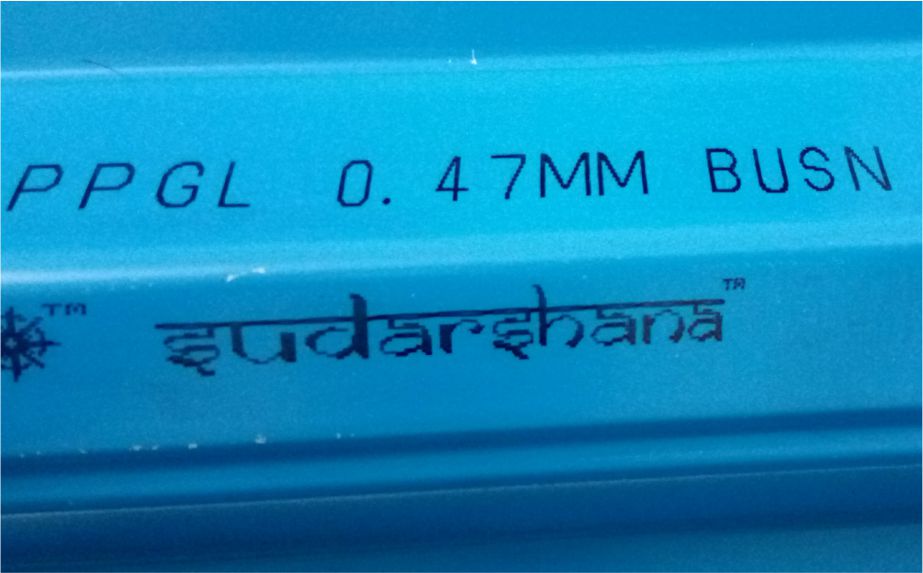

Print Specification: The customer is required to print the brand name, ISI logo, and product details on the GI sheet.

Technology Shift : The customer was using older competition CIJ printers and had frequent breakdown due to Nozzle blocking, furthermore the consumption rate of consumable was very high.

Code Quality & Consistency: Maintaining consistent print quality on GI sheet & pipes can be challenging, as the manufacturing environment was harsh due to dust particles & temperature fluctuation.

KGK Jet Solution

KGK Jet CCS3100: Versatile small character CIJ printer with IP65 ingress protection, perfect for the demanding manufacturing conditions in the subcontinent. It offers high-speed coding capabilities and can manage multiple production lines simultaneously.

Ease of Operation: The CCS3100 comes with a detachable 10.5-inch color touchscreen and boasts an intuitive, user-friendly interface. This single master machine can control up to 16 slave machines, making it ideal for a fast-paced production environment.

Conquering Harsh Environments: Equipped with positive air pressure in the print-head, KGK Jet CIJ machines keep out dust and moisture, avoiding any risk of print head and ink contamination. The unique Nozzle Capping technology seals the nozzle when the printer is not active, safeguarding the ink and reducing the frequency of cleaning required by operators.

Most Economical: CCS3100 with CN505 black ink was suitable for wide varity of substrate, proved most economical to operate due 50micron nozzle. As per calculation custom find it 30% more economical then other CIJ machines.

Fast Changeover: The CCS3100 can store up to 999 messages, making it convenient for machine operators to quickly changeover production lines. Its compact design allows the print head to fit into tight spaces on the production line.

Service Support: KGK Jet CIJ machines are equipped with a Service Management System (SMS) that triggers preventive maintenance, helping to prevent breakdowns and enhance operational efficiency.

Key benefits of CCS3100:

Simple, Efficient and Stable: Freedom to edit 1 to 6 lines of text, serial number, linear bar code, QR code as well as graphics and logo.

Sturdy Nozzle Head: To enhance work efficiency, printhead has been designed for quick changeover between lines and can operate in a smaller space.

Built for rugged use: 10.4 inch coloured touch panel for faster operations . One master machine can control up to 16 slave machines

Unique diaphragm pump advantage: KGK Jet's ink delivery system is powered by a diaphragm pump. These pumps are more efficient and reliable than geared pumps. A diaphragm pump component does not come in contact with ink and solvent this prevents fluid contamination.

Extended language support & Weighing machine connectivity: Language support for both software & hardware including English, Arabic, Chinese, Korean, Italian, German, Spanish, Iranian & Turkish

Simple & convenient to integrate with on-line or off-line check-weigher machine of any brand through RS-232, TCP/IP(LAN) with the support of weighing machine suppliers.

Superior printing function: A single nozzle has a maximum longitudinal marginal space of 36 dots which is flexible to meet special information compilation requirements. Customers can freely edit 1-6 lines of text, serial number, linear bar code QR/2D barcode as well as graphics, logo & QR code.

Key Reasons for Choosing KGK Jet:

- Ink manufacturing facility in India for product pre or post-sales support.

- Integrating KGK solution without disturbing existing production line.

- Quick & proficient service team who responds to 24x7 customer queries.

- Our Japanese DNA for continuous research & improvement of product & services.

Customer Benefits

- The KGK Jet solution allows customers to concentrate on other essential business processes instead of having to manage their CIJ printer.

- The make up consumption rate was 30% lower than the previously installed CIJ printers.

- Due to IP65 protection & positive air, the printer work non-stop during trail and after.