Optimized Coding and Marking for the Dairy Industry by KGK Jet

Company Profile: Dairy brand specializing in the production and distribution of milk and milk products, including curd, ghee, paneer, and butter.

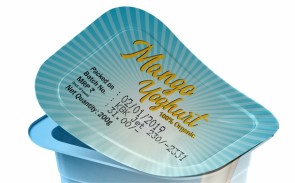

Non Contact Coding: To eliminate the risk of potential contamination, the customer requires a non-contact coding solution that is compatible with packaging substrates such as PP bags, laminated cartons, and PET film.

Challenging Environmental Conditions: Hygiene standards in dairy manufacturing require regular water wash of the packaging area. A high-moisture environment calls for a coding solution that is durable and capable of performing reliable, flawless coding.

Unplanned Breakdown: The customer needs multiple coding machines for 24/7 dairy product manufacturing which has short shelf life. Unplanned breakdown may affect production and profit.

Consumables Cost: Customer is expecting more cost-effective coding and faster coding technology.

KGK Jet Solution

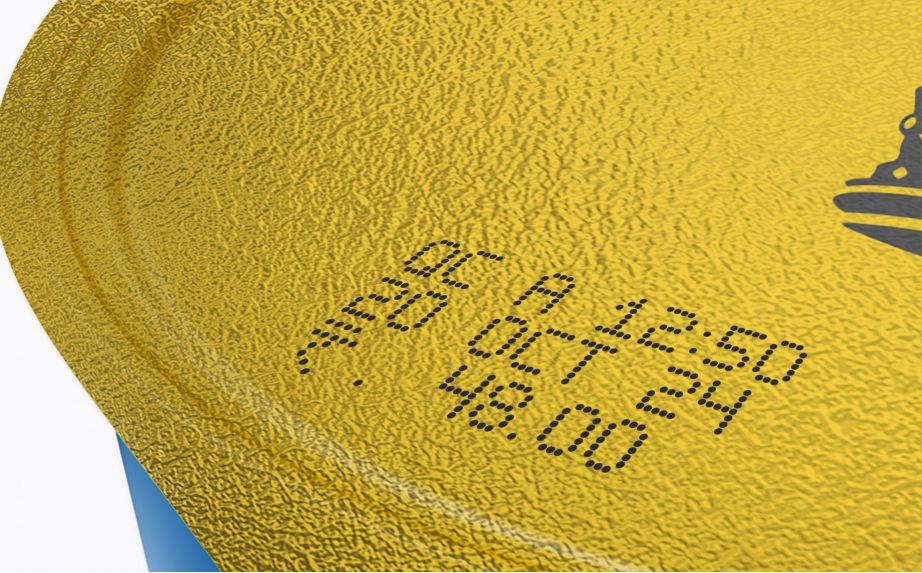

CS3000 CIJ Machine: KGK Jet six-line CIJ machine with matches customer expectation with non stop production and crisp coding from first to last print.

Ease of Operation: The CCS3000, featuring IP 65 ingress protection, comes with a detachable 10.5-inch coloured touchscreen and an intuitive, user-friendly interface for easy operation.

Non Stop Coding: Equipped with positive air pressure in the print-head, KGK Jet CIJ machines keep out dust and moisture, avoiding any risk of print head and ink contamination. The unique Nozzle Capping technology seals the nozzle when the printer is not active, safeguarding the ink and reducing the frequency of cleaning required by operators.

Extended Language Support: Language support for both software & hardware including English, Arabic, Chinese, Korean, Italian, German, Spanish, Iranian & Turkish

Most Economical: CCS3000 with CN505 black ink was suitable for wide verity of substrate, proved most economical to operate due 50micron nozzle. As per calculation custom find it 30% more economical then other CIJ machines.

Fast Changeover: CCS3000 can store up to 999 messages which machine operator’s find very convenient for quick changeover of production line.

Service Support: KGK Jet CIJ machines are equipped with a Service Management System (SMS) that triggers preventive maintenance, helping to prevent breakdowns and enhance operational efficiency.

Key benefits of CCS3100:

CCS 3100: KGK Jet CCS3100 CIJ machine with IP65 ingress protection is non-contact printing technology, allowing it to print on irregular, curved, or uneven surfaces without direct contact. This makes it versatile for printing on a wide range of shapes and substrates.

Most economical: The CCS3100 the most cost-efficient to operate, largely due to its 50-micron nozzle. Based on calculations, the customer concluded that it is 30% more economical than other CIJ machines.

Service support: The KGK Jet service engineers responded promptly during the demonstration, making adjustments during installation and quickly resolving all inquiries. Additionally, KGK Jet CIJ printers are equipped with a Service Management System (SMS) that triggers preventive maintenance, helping to prevent breakdowns and enhance operational efficiency.

Key Reasons for Choosing KGK Jet:

• Ink manufacturing facility in India for product pre or post-sales support.

• Integrating KGK solution without disturbing existing production line.

• Quick & proficient service team who responds to 24x7 customer queries.

• Our Japanese DNA for continuous research & improvement of product & services.

Customer Benefits

- Customer has faster changeover between production line and save crucial packaging time for product with shorter shelf life.

- Thanks to Nozzle capping & Auto Start & Stop feature operators has minimal head cleaning in high moisture production environment.

- Consumption of consumable are also low.