Baking Business Cuts Coding Costs by 30 percent with KGK Jet Batch Code and MRP Printing Machine

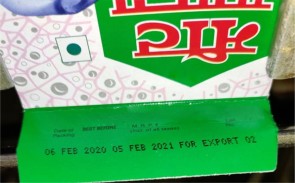

Bakery manufacturers are known for biscuits, cookies, and confectionery, well known brand, extending their reach to international markets. For their 24-hour production line in India, the manufacturer requires a coding and marking machine.

Challenges & Opportunities

24x7 production line: Complement market demand customer’s production runs 24x7 in various shifts. It is vital for coding machine to complement the non-stop production.

Poor Ink Management: Due to previous experiences with ink leaving marks on machines, hands, clothing, and occasionally compromising food packaging, operators were not enthusiastic about working with CIJ machines for food packaging.

Requires Swift Line Changeover: Customer has variety of biscuits, cacks & chocolate variants which requires quick line changeover without wasting vital production time.

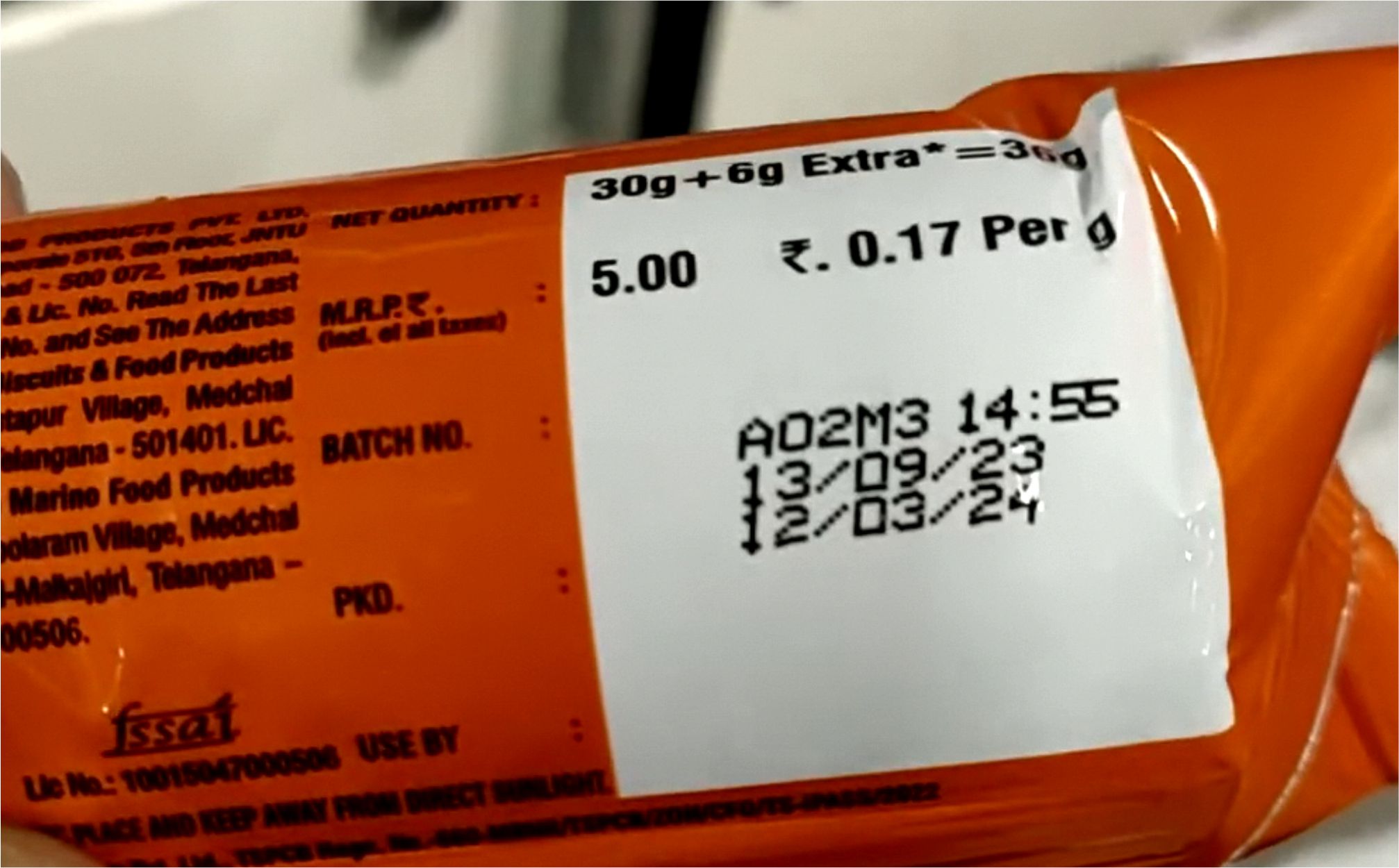

Brand Equity: Consistent quality coding for each packaging was a priority for the customer, as it could impact the brand and profitability if consumers are unable to read the codes easily.

KGK Jet Solution CCS3000L

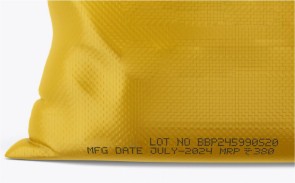

Increased Production Speed: Equipped with 4-line coding capabilities, the CCS 3000L effortlessly matched the required production speeds. When the customer moved to a high-volume, low-cost production model for Rs. 5 and Rs. 10 biscuit packages, they recognized that the previous TTO coding technology couldn't meet the speed demands of the online packaging line.

Optimize Manufacturing Expenses: Increased production speed up to 150 packets per minute, CCS3000L per print cost reduced half than previous coding method. KGK Service Management System prevent unscheduled breakdown cut employee ideal time during curtail production led to significant saving for the customer.

High Reliability: Online packaging lines require trustworthy coders, operators were forced to stop 24/7 product production to clean nozzles at least 15 to 20 minutes between each shift, incurring production & labour losses. Using patented nozzle capping technology, the CCS3000L has proved to be a reliable production partner that does not require frequent nozzle cleaning.

User Friendly Interface: Multiple line changeover in a day operators need not to add codes each time. CCS3000L's easy-to-use interface allows for quick access to code stored in memory, including MRP, packaging date, expiry date, and batch code. This improves operators’ efficiently and preventing errors.

Key benefits of CCS3000L:

- Operational efficiency : KGK patented Nozzle Capping Technology close the print nozzle when the printer is not in use. This prevents Ink from drying and frequent line clogging. CCS3000L ensure 24x7 non-stop production with no clogging, no cleaning, simply smooth printing.

- Accuracy & Adaptability: CCS3000L can code easily on small packaging thanks to 50-micron nozzle size. Complimenting vast customer’s packaging portfolio of various size & different substrate CCS3000L quickly adopt to line change over.

- Faster start : Auto start-stop feature designed to auto maintain and schedule start the machine immediately even if machine is not operated for very long time. This feature minimises servicing needs at the same time as reducing consumable use, results in high uptime and a low cost of ownership.

- Positive Air Pressure Protection: Print head is installed horizontally close moving packaging prone to dust and moisture buildup inside printhead. CCS3000L print-head equipped with Positive air guard guards protects against splash back ink buildup & dust and humidity from entering the print head.

Key Reasons for Choosing KGK Jet:

- KGK Pan India installation in similar industry & team in-depth knowledge.

- Ink manufacturing facility in India for product pre or post-sales support.

- Integrating KGK solution without disturbing existing production line.

- Quick & proficient service team who responds to 24x7 customer queries.

- Our Japanese DNA for continuous research & improvement of product & services.

Customer Benefits

- Comprehending customer production and proposing solutions without any modifications in production line.

- 24x7 non stop, accurate & reliable coding on multiple substrate.

- Reduce cost of ownership through savings on consumables and eliminating production losses.