Masala King Adds Business Flavor using KGK Jet Batch Coding Machine

Customer Profile: Manufacturers of whole spices, organic spices, spice mixes, and spice blends utilize packaging in the form of carton boxes and pouches available in three different sizes. Need Marking & coding solution for Batch Coding Machine.

Challenges & Opportunities:

Competition CIJ: The customer is currently operating 15 CIJ machines from a competitor and is experiencing issues due to the age of the machines.

Space constrains: CIJ was used by customers with a 6-meter umbilical cable due to limited manufacturing space.

High ink consumption: Competition CIJ machines with old technology consuming high ink & solvent every month.

Line Changeover Delay: Customer need to change production line at least 4-5 time in a day, each changeover requires 15-20 minutes, causes production loss.

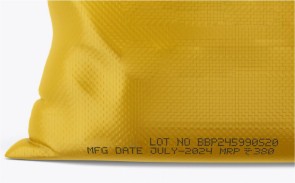

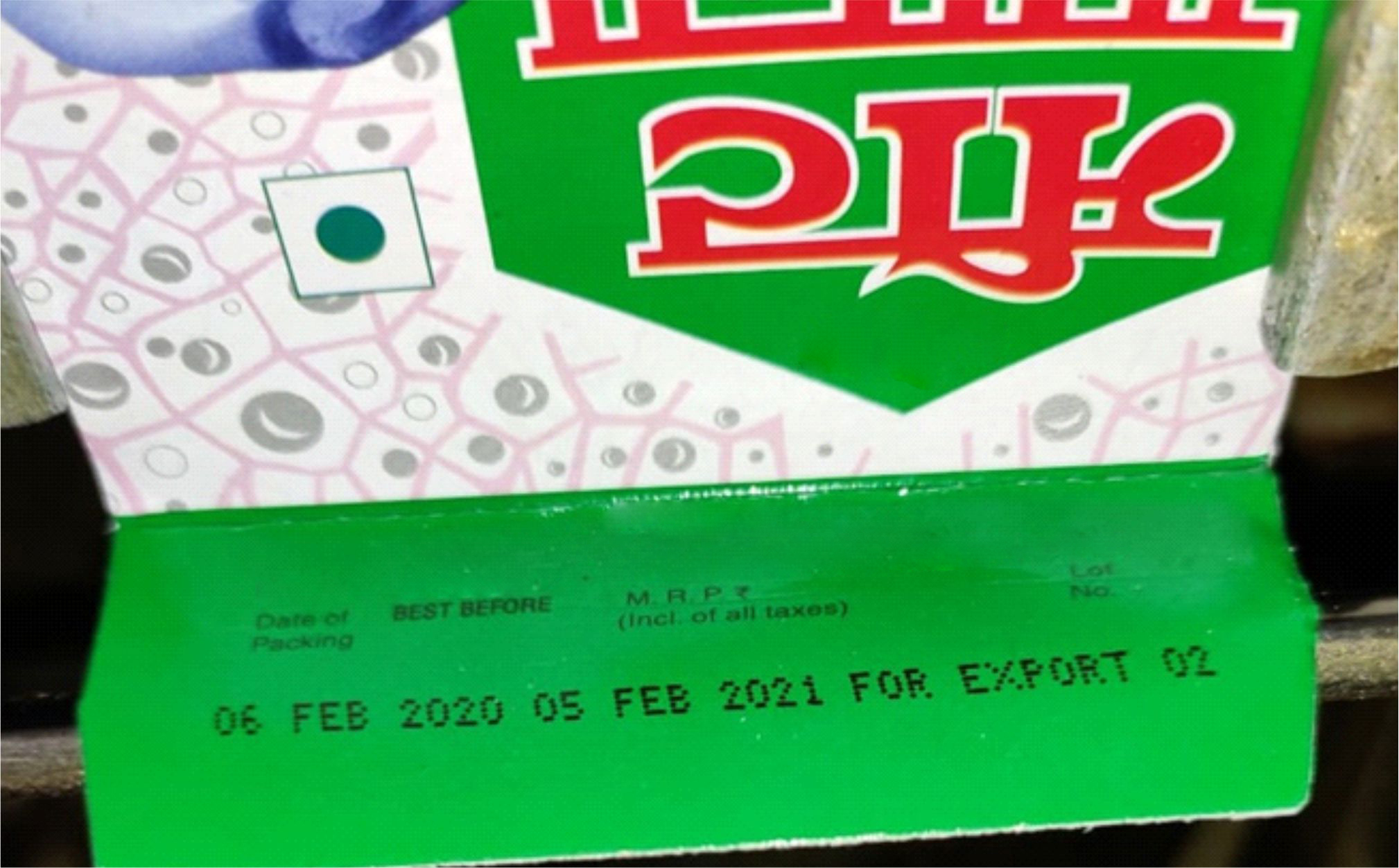

Multiple substrate: Laminated cartons & pouch need marking & coding using FFS & conveyer belt application. Need singe ink for all the substrates.

Reasons for choosing CCS-R:

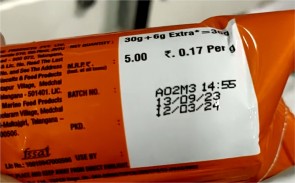

Fast coding: Due to increased coding speed, the existing line has been modified from a previous conveyor application to a horizontal filling machine, which now processes 30-40 packages per minute.

Ergonomically Design: The KGK Jet CCS-R was an ideal solution for the customer's needs, featuring batch coding and MRP coding. Its print head is compact, accommodating tight spaces, and solution fits in with KGK Jet's standard 3 meters of umbilical cable.

Fast changeover: CCS-R ability to store message results in faster line changeover for customer.

Robust Design : Robust & versatile keyboard and screen design proves operators friendly in daily operations.

Key benefits of CCS-R:

Simple, Efficient and Stable: Freedom to edit 1 to 4 lines of text, serial number, linear bar code, as well as graphics and logo.

Sturdy Nozzle Head: To enhance work efficiency, printhead has been designed for quick changeover between lines and can operate in a smaller space.

Built for rugged use: Keyboard & screen is built to be highly responsive and accurate, while also providing a longer lifespan.

Key Reasons for Choosing KGK Jet:

- References from existing customers has built confidence & KGK Jet team in-depth knowledge of the industry.

- Ink manufacturing facility in India for product pre or post-sales support.

- Integrating KGK solution without disturbing existing production line.

- Quick & proficient service team who responds to 24x7 customer queries.

- Our Japanese DNA for continuous research & improvement of product & services.

Objectives:

- Customer is happy with CCS-R performance & production line integration.

- Achieve 100% uptime with KGK Jet's on-site service support, complemented by SMS for proactive preventive maintenance.

- Reducing ink and consumable costs accelerates the customer's return on investment.